Types of Concrete Joints: All You Need To Know

Last updated on March 31st, 2022

Definition of joints in concrete

A concrete joint can be defined as an interface, separation, or weakened plane that is created or designed to serve a specific purpose, depending on its type.

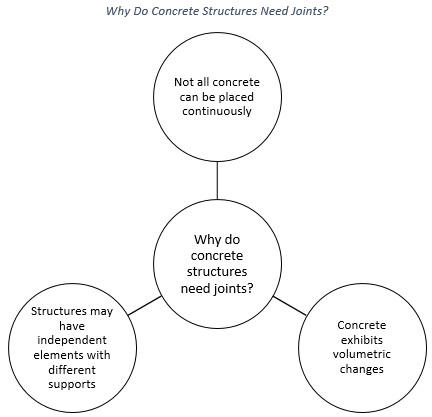

Why do concrete structures need joints?

Concrete structures require joints for three main reasons:

- The first is related to the workflow, where not all concrete can be placed continuously.

- The second is related to the concrete as a material, in which it exhibits volumetric changes mainly due to shrinkage and temperature.

- And, the third is related to the design and application, where structures may have independent elements with different support conditions.

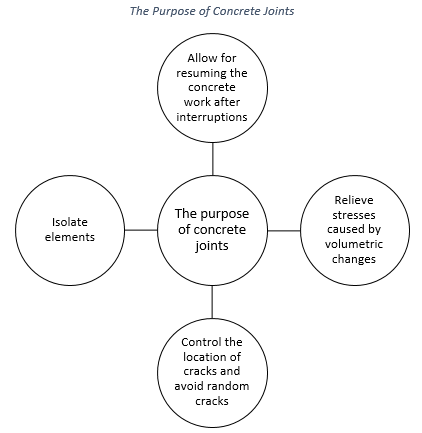

Purpose of concrete joints

Thereby, the purpose of joints is to:

- Allow for resuming the concrete work after interruptions.

- Relieve stresses due to volumetric changes.

- Control the location of cracks and avoid random cracks.

- Isolate elements.

However, depending on the type of the joint, it can serve one or more of these purposes.

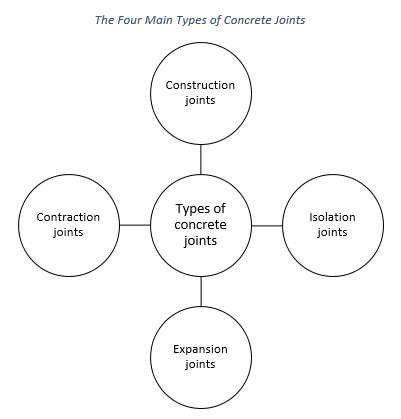

Types of joints in concrete

Mainly, there are four types of joints in concrete: construction, isolation, expansion, and contraction joints.

1. Construction joints

A construction joint is basically an interface between two concrete pours, with a time interval longer than the initial setting time of the first. Hence, this type of joints is created to allow for resuming or continuing the concrete work after interruptions. In fact, these interruptions can be either intentional or unintentional.

Intentional or planned interruptions are mainly related to the fact that it is simply impractical to place all concrete continuously, or to the use prefabricated elements. Whereas, unintentional interruptions include any unplanned termination of the concrete work, generally due to equipment failure, accidents, unexpected weather conditions, or delays.

In general, a good practice is to coincide construction joints with other types of joints, if possible, depending on the location and type of the construction joint.

Types of construction joints

In general, there are four types, or configurations, of construction joints, including keyed, dowelled, bonded, and butt joints.

a. Keyed

A keyed construction joint is an interface which allows for load transfer between segments. However, bare keyed construction joints are not so common, and can cause spalling with inadequate dimensions. In general, such joints are suitable when they coincide with contraction joints.

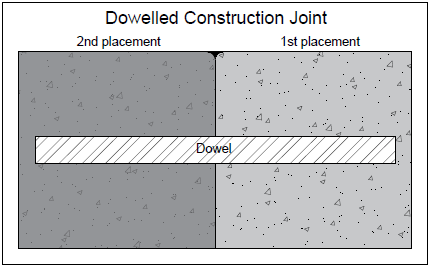

b. Dowelled

A dowelled construction joint is an interface which allows heavy load transfer through smooth or sometimes deformed dowels, which an aggregate interlock cannot bear. In general, such joints consist of smooth dowels bonded to one side, and lubricated on the other side. But in some cases, hooked or deformed bars are used.

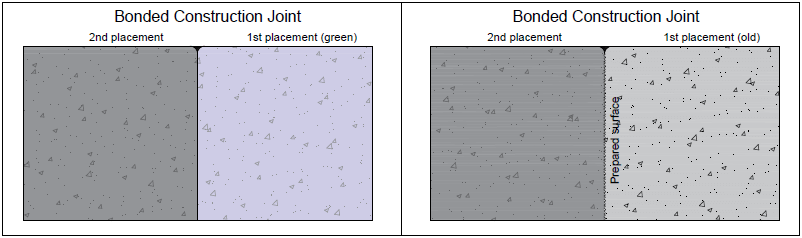

c. Bonded

A bonded construction joint is an interface which permits the continuous transfer of loads, and thus flexure and shear stresses. Otherwise, without proper load transfer, the interface would be weak and the joint would serve as a contraction joint. In general, this type is applicable when it does not coincide with contraction joints.

Besides, this type of construction joints requires the concrete surface to be clean and free from laitance and debris, in case the concrete is still new. However, in case the concrete is old, then it requires surface preparation. In addition, in unreinforced members, using tie bars across the joint can limit its opening.

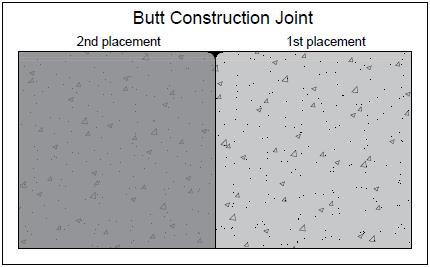

d. Butt

This type of construction joints does not provide flexure and shear continuity. Thus, it is only suitable in applications where load transfer is not of a concern, and when it does not coincide with other types of joints. However, when load transfer is a major factor, such joints require dowels, keys, or thickened edges.

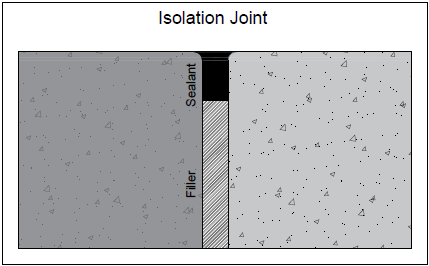

2. Isolation joints

An isolation joint is a separation that completely isolates the movement between two elements. Accordingly, such joints are full depth and do not permit any continuity in steel reinforcements and obviously concrete. Hence, they do not allow for load transfer.

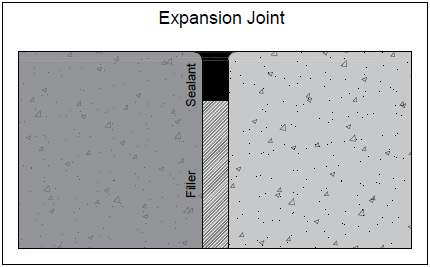

3. Expansion joints

An expansion joint is a gap having an adequate width to remain effective under volumetric changes. In particular, this type of joints aims to reduce the stresses induced by volumetric changes due to temperature, by allowing portions to expand and contract without getting in contact with each other.

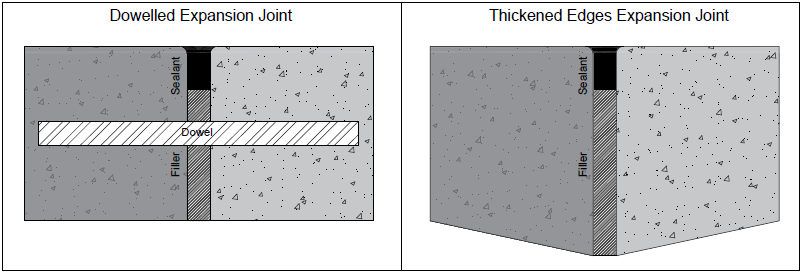

Unlike isolation joints, expansion joints are usually dowelled or sometimes edge-thickened, to allow movement and some load transfer.

4. Contraction or “control” joints

A contraction joint can be defined as an intentionally formed weakened plane, through reducing the cross-section by a minimum of 25 percent. Specifically, it aims in controlling the location of cracks and avoiding the formation of random cracks caused by volumetric changes through relieving internal stresses, mainly in walls and slabs on ground. In fact, volumetric changes are mainly caused by shrinkage and temperature.

However, when concrete exhibits volumetric changes, and its movement is restrained, stresses will form. Mainly, if the tensile stresses exceed the tensile strength of concrete at a specific time, concrete will crack. But, contraction joints, which represent a weakened plane having a relatively smaller thickness, help in controlling the location of these cracks when they have a proper location, configuration, and spacing.

Besides, this type of joints transfers stresses along different segments, either through aggregate interlock, keys, or dowels.

Types of contraction joints

In general, there are three types of contraction joints, including basic weakened plane, keyed, and dowelled joints.

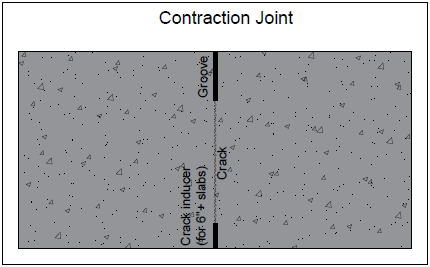

a. Basic weakened plane

A weakened plane contraction joint is basically a joint with reduced cross-section. This reduction can be done through a groove by tooling, saw cutting, or inserting a specific pre-molded insert or a preformed strip, in addition to adding crack inducer in some cases.

This type of contraction joints transfers loads between segments through aggregate interlocking.

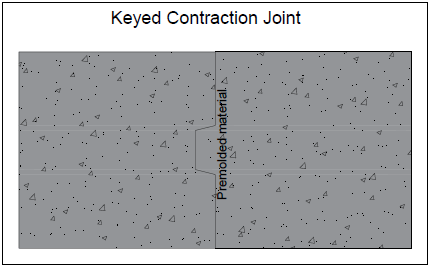

b. Keyed contraction joint

A keyed contraction joint is also a weakened plane but formed with a pre-molded material resembling a key. This type of contraction joints allows for load transfer through the preformed key, while also allowing horizontal movements.

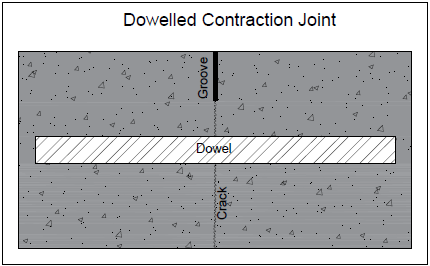

c. Dowelled contraction joint

A dowelled contraction joint is also a weakened plane, however with the addition of dowels. This design is more suitable for heavily loaded slabs, and allows for load transfer through segments, while also allowing for horizontal movements. In such joints, the dowels must be smooth and either bonded on one side and lubricated on the other, or lubricated on both sides.