The Best Acrylic Sealers for Stamped Concrete: All You Need To Know

Last updated on March 23rd, 2022

Stamped concrete can be aesthetically appealing and can add a decorative touch to your property. However, it can be exposed to different harsh conditions. These conditions include ultra-violet radiations, freeze and thaw cycles, abrasion, stains, deicers, salts, and hot tires. Hence, it is important to protect it with the right type of sealers.

Not every stamped concrete project is similar

“There is no single sealer that is ideal for every stamped concrete application”.

In fact, there are various factors that you need to consider in order to make the right choice on the ideal sealer for your project.

Even a simple question such as the location, can introduce important variables to consider. For example, a stamped concrete driveway project in Miami has different exposure conditions than a similar project in Milwaukee. Not only the climate and temperature ranges are different, but also the exposure to salts and deicers.

You can find out more about the in-depth process of choosing the ideal sealer for concrete floors in general, the factors that you should consider, and how to compare alternatives, in the following article, “How to Choose the Best Sealers for Concrete Floors“.

The main factors include aesthetic preferences, weather and exposure conditions, application, surface condition, environmental impact, and cost. Hence, determining these factors can help in putting your choice on the track towards choosing the right type of sealer. Then, by considering the safety, durability, overall performance, and appearance, you can determine the ideal sealer for your specific project.

However, without going through every technical aspect, this article generally introduces the best acrylic sealers for various stamped concrete applications in different conditions.

The commonly used sealers for various stamped concrete applications

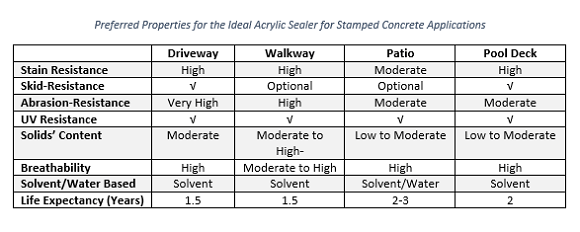

Stamped concrete is popular in driveways, walkways, patios, and pool decks. Generally, each of these applications has different exposure conditions, which can affect your choice on the best sealer. In fact, even in the same application category, the characteristics of the ideal sealer may vary depending on several factors, as we mentioned previously.

The most common sealers for stamped concrete include acrylic sealers, penetrating sealers, and hybrid sealers. However, acrylic, which is a film-forming sealer, is the most popular. What makes it popular for such applications is that it is budget-friendly, easy to apply, and it enriches the colors of stamped concrete with various levels of sheen. Also, it generally owes other characteristics which makes it suitable for most stamped concrete applications.

However, there are plenty of acrylic sealers in the market, with different quality, composition, and specifications. Hence, it is important to know what to look for, and choose the product that meets the requirements of your project.

Thereby, apart from factors such as the aesthetic preferences, cost, ease of application or reapplication, ease of repair, and drying time, the following sections illustrate the essential properties to look for in the ideal acrylic sealers for stamped concrete applications.

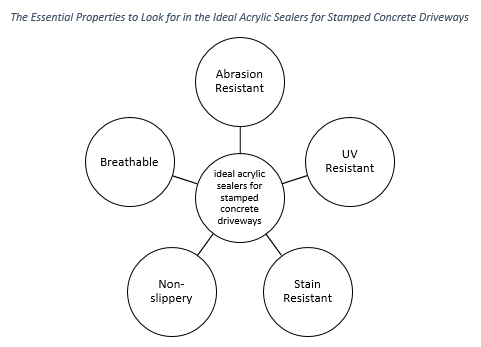

Stamped concrete driveways

Driveways are often subjected to relatively harsh exposure conditions when compared to walkways, patios, and pool decks. These exposure conditions include ultra-violet (UV) radiations, tire loads, hot tire marks, oil, salts, deicers, and moisture. Thereby, the best acrylic sealers for stamped concrete driveways should be resistant and provide protection against such exposure conditions.

What to look for when choosing the ideal sealer for your driveway?

Based on the general exposure conditions of stamped concrete driveways, the right type of sealer should be:

- Abrasion resistant: A driveway sealer should have a good resistance to abrasion, due to its exposure to tire loads and friction.

- Resistant to ultra-violet (UV) radiations: It should remain stable and not be sensitive to ultra-violet radiations. The main concern is that an inadequate sealer can start yellowing with time.

- Stain-resistant: It should have a good resistance to stains due to its exposure to oil, water, salts, and various chemicals.

- Non-slippery: One of the most important aspects in driveways is safety. In fact, driveways often have slopes, which further increases the importance of safety especially in cold climates.

- Breathable: Breathability is a necessary characteristic of a good driveway sealer. It is important to ensure that the sealer does not trap moisture, which can eventually be harmful to the concrete, and can also cause aesthetic problems.

The best acrylic sealers for stamped concrete driveways

Based on the general requirements and exposure conditions of stamped concrete driveways, it is usually best to choose an acrylic sealer which is of a high quality, solvent-based, with moderate solids’ content, in addition to the use of a skid-resistant additive. On average, such sealers last about 1.5 years on driveways.

In general, a high quality solvent-based acrylic sealer performs better than a water-based acrylic sealer in such conditions. In addition, a solvent-based sealer enriches the colors of stamped concrete more than a water-based one does.

Also, the solids’ content is an important aspect to consider. Generally, acrylic sealers with lower solids’ content yield a thinner topical coat, which is more breathable, but less resistant and less durable than that of acrylic sealers with higher solids’ content, and vise-versa. However, considering the general exposure conditions of stamped concrete driveways, both breathability and durability are necessary. Thereby, a balanced solids’ content is most suitable.

Furthermore, a topical sealer can be slippery with water and oil on top, especially with sloped driveways. Thus, a skid-resistant additive is necessary.

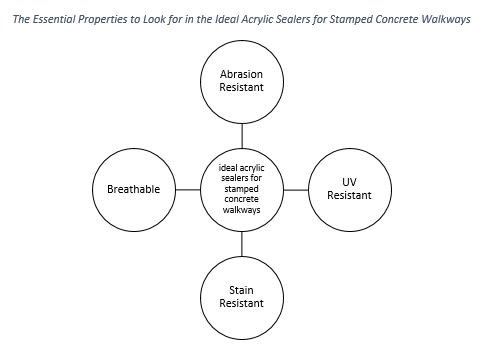

Stamped concrete walkways

Walkways are usually subjected to ultra-violet radiations, heavy foot-traffic, salts, deicers, and moisture. Hence, the ideal acrylic sealers for stamped concrete walkways should provide protection against such exposure conditions.

What to look for when choosing the ideal sealer for your walkway?

The ideal sealers for stamped concrete walkways should generally be:

- Abrasion resistant: A walkway sealer should have a good resistance to abrasion, due to heavy foot-traffic.

- Resistant to ultra-violet (UV) radiations: It should not be sensitive to ultra-violet radiations, thus being non-yellowing.

- Stain-resistant: It should have a good resistance against various stains, due to its exposure to water, salts, and various chemicals.

- Breathable: It should also be breathable to avoid moisture entrapment.

The ideal acrylic sealers for stamped concrete walkways

In general, it is best to choose a high-quality acrylic sealer which is solvent-based, having a moderate to high solids’ content. On average, such sealers last about 1.5 years on walkways.

Usually, solvent-based acrylic sealers perform better than water-based ones on stamped concrete walkways. This is mainly because they are more resistant and durable to the heavy foot-traffic.

Also, when it comes to the solids’ content, a range between moderate to high is usually most suitable. Similar to stamped concrete driveways, both breathability and durability are necessary in stamped concrete walkways. However, a slightly higher solids’ content is applicable for the latter, briefly due to its shape benefits on breathability. Hence a moderate to high solids’ content provides a good balance between breathability and durability/resistance.

It is important to note that, as the solids’ content decreases, the breathability increases. However, this often compromises in durability and resistance.

Stamped concrete patios

Patios are usually subjected to less harsh conditions when compared to driveways or walkways; they are not exposed to tire loads, salts, deicers, oils, tire marks, or heavy foot-traffic. However, their main exposure conditions include ultra-violet (UV) radiations, light foot-traffic, and moisture.

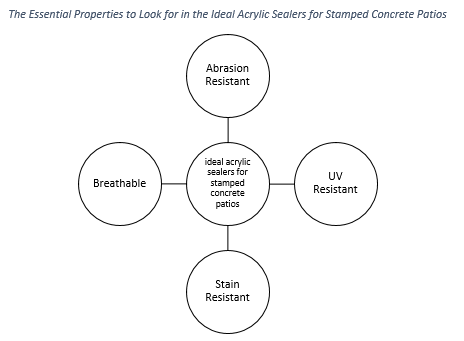

What to look for when choosing the best sealer for your patio?

Based on the general exposure conditions, the ideal sealers for stamped concrete patios should be:

- Abrasion resistant: An ideal patio sealer should be able to resist the abrasion due the light foot-traffic, furniture, and point loads.

- Resistant to ultra-violet (UV) radiations: It should remain stable and be be non-yellowing in the exposure of direct sunlight.

- Stain-resistant: It should have a good resistance against stains, due to its exposure to weathering conditions, spills, flower pots, and others.

- Breathable: In addition, patio sealers should be breathable, in order to prevent moisture entrapment.

The best acrylic sealers for stamped concrete patios

Considering the general requirements and exposure conditions, the best acrylic sealers for stamped concrete patios should be of a high quality, water-based or solvent-based, with low to moderate solids’ content. On average, these sealers last about 2 to 3 years on patios.

In general, the exposure conditions of patios are relatively mild. Thus, both solvent-based and water-based acrylic sealers are applicable to be ideal. In fact, the ideal choice is more related to aesthetics and environmental impact in such applications. Mainly, solvent-based acrylic sealers tend to give a richer and darker color with higher sheen than water-based acrylics. In addition, water-based acrylic sealers are more environmental-friendly.

Also, the ideal acrylic sealers for stamped concrete patios usually should have low to moderate solids’ content. This is mainly due to the relatively mild exposure conditions and the necessity of breathability.

When compared to driveways or walkways, patios are not exposed to harsh conditions such as tire loads, hot tire marks, and heavy foot-traffic. However they are exposed to weathering conditions, which makes breathability a governing factor. Hence, the low to moderate solids’ content will provide high breathability while still providing enough durability and resistance.

Stamped concrete pool decks

Pool decks are usually exposed to ultra-violet (UV) radiations, oil, salts (in case of saltwater pool), chemicals (such as chlorine), and moisture. Thereby, the best acrylic sealers for stamped concrete pool decks should be provide high protection against these conditions.

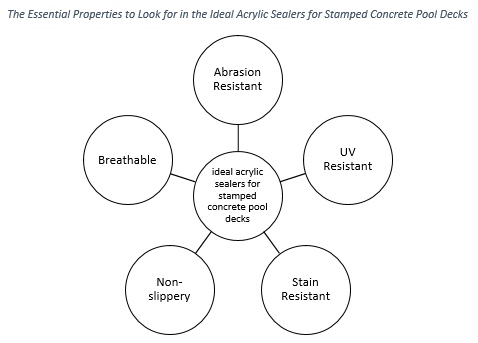

What to look for when choosing the best sealer for your pool deck?

The best sealers for stamped concrete pool decks should be:

- Abrasion resistant: A good pool deck sealer should be somewhat resistant to abrasion, due to furniture and light foot-traffic.

- Resistant to ultra-violet (UV) radiations: It should not be sensitive to ultra-violet radiations, thus being non-yellowing.

- Stain-resistant: It should have a high resistance to stains, due to its exposure to oil, water, salts, and chlorine.

- Non-slippery: Safety is a major factor in pool decks. In fact, water and oil on top of a topical sealer can significantly increase slipperiness, which makes it a major safety concern.

- Breathable: It should also be breathable due to its exposure to weathering conditions and hydrostatic water pressure.

The best acrylic sealers for stamped concrete pool decks

Considering the general exposure conditions of stamped concrete pool decks, it is usually preferred to choose a high quality acrylic sealer which is solvent-based, with low to moderate solids’ content, and most importantly with the use of a skid-resistant additive. On average, such sealers last about 2 years.

Usually, high quality solvent-based acrylic sealers for stamped concrete pool decks provide higher resistance to to stains, salts, chemicals, and chlorine, than water-based ones.

Also, a low to moderate solids’ content provides high breathability and sufficient protection against the relatively moderate exposure conditions.

In addition, the use of a skid-resistant additive increases the traction and reduces slipperiness, which is crucial in pool deck applications. In fact, a stamped concrete pool deck can be aesthetically pleasant. However, it can be a slip hazard as well, especially with water and sunbathing oil spills on top of a topical sealer. Hence, a skid-resistant additive is often necessary.

Summary of the best acrylic sealers for different stamped concrete applications

As a brief conclusion, each of the four stamped concrete applications (driveways, walkways, patios, and pool decks) have different general exposure conditions and requirements. Thereby, the essential properties of the ideal acrylic sealer for each are somewhat different.