The Important Ten Types of Portland Cement

Last updated on March 23rd, 2022

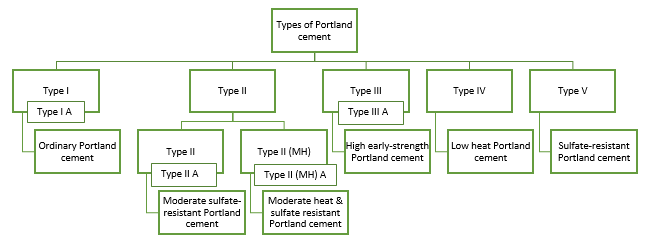

The ten types of cement and uses

ASTM C150 separates Portland cement into 10 different cement types under five main categories, as follows.

Type 1 Portland cement

Type 1 is an ordinary Portland. It is suitable for general purposes with no special extenuating conditions.

Type 2 Portland cement

Type 2 is a moderate sulfate resistant cement. This type of cement is used in structures exposed to moderate sulfate attacks. However, Type 2 (MH) is not only moderate sulfate-resistant, but also a moderate heat-generating Portland cement. Thus, it is suitable for structures subjected to moderate sulfate attacks and where heat of hydration is of a concern.

Type 3 Portland cement

Type 3 is a high early strength Portland cement. It is suitable for applications such as repairs or cold weather concreting.

Type 4 Portland cement

Type 4 is a low heat Portland cement. It is usually beneficial in mass concrete and hot weather concreting.

Type 5 Portland cement

Type 5 is a sulfate resistant Portland cement. It is usually used in applications where concrete is subjected to sulfate attacks, such as marine structures or chemical plants.

In addition, types 1A, 2A, 2(MH)A, and 3A are air-entrained types of Portland cement. They are similar to types 1, 2, 2(MH), and 3 respectively, however, with the addition of an air-entraining agent during the manufacturing process. Air-entraining agents help in providing an increase in the freeze and thaw resistance.

The difference in the chemical composition between the different cement types

The chemical composition significantly affects the properties of different Portland cement types. In brief, Portland cement consists mainly of four chemical compounds.

The main chemical compounds in cement

- Tri-calcium aluminate (C3A): This compound generates high heat during the hydration mechanisms of cement. In addition, it has very low resistance to chemical attacks.

- Tri-calcium silicate (C3S): This compound generates medium heat during the hydration mechanisms of cement. Moreover, it mainly contributes to the early strength development. However, it has a low resistance to chemical attacks.

- Di-calcium silicate (C2S): This compound generates low heat during the hydration mechanisms of cement. Also, it mainly contributes to the long-term strength. In addition, it has a moderate resistance to chemical attacks.

- Tetra-calcium aluminoferrite (C4AF): This compound generates moderate heat during the hydration mechanisms of cement. Moreover, it has high resistance to chemical attacks.

You can read more about the composition and hydration mechanisms of cement and the characteristics of its reactants and products in the following articles:

- Composition and Hydration Mechanisms of Cement

- Characteristics of the Reactant Compounds & Hydration Products of Cement

What makes each type of Portland cement chemically unique

Thereby, for type 2 Portland cement, which is moderate sulfate-resistant, the standard limits the amount of tri-calcium aluminate (C3A).

For type 2 (MH) Portland cement, which is moderate sulfate-resistant and moderate-heat generating, the standard limits the amount of tri-calcium aluminate (C3A). In addition, it also limits the amount of a certain combination of tri-calcium silicate (C3S) and tri-calcium aluminate (C3A).

For type 3 Portland cement, which provides high early-strength, the standard increases the amount of tri-calcium silicate (C3S).

For type 4 Portland cement, which has low heat generation, the standard increases the amount of di-calcium silicate (C2S).

And finally, for type 5 Portland cement, which is sulfate-resistant, the standard limits the amount of tri-calcium aluminate (C3A) even more than that of type 2. Furthermore, it limits a certain combination of tri-calcium aluminate (C3A) and tetra-calcium aluminoferrite (C4AF).

Conclusion

Based on ASTM C150, there are ten different cement types under five main categories. In addition, these types can vary in their chemical composition and uses. You can find out more about these types by referring to the aforementioned ASTM code.