How to Choose the Best Sealers for Concrete Floors

Last updated on March 23rd, 2022

Selecting the best sealer for concrete floors

Choosing the best sealers for concrete floors can be a difficult choice to make. In fact, there are various types of sealers in the market, and plenty of brands marketing their products as the best out there. However, there are many factors to consider when choosing the best sealer.

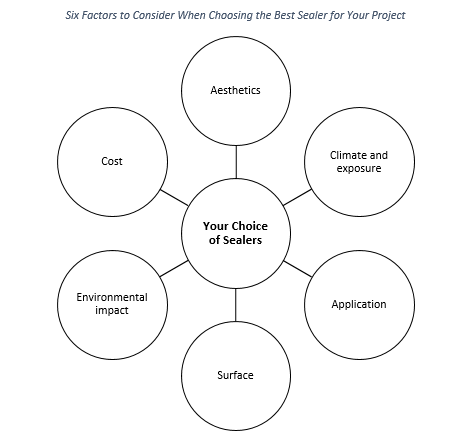

Six factors to consider

In brief, the six most important factors include aesthetics, climate and exposure conditions, application, surface, environmental impact, and short-term and long-term costs.

Aesthetics

When it comes to appearance, both your personal preference and the surrounding design have a great impact on your choice. With that being said, concrete sealers can alter the appearance of concrete with sheen and color. For example, if you decide to give your concrete a “wet look” effect, you should probably stick to film-forming sealers. These include acrylics, polyurethanes, epoxies, and others. Whereas, if you choose to keep a natural appearance to your concrete without any additional effects, then your best choice is penetrating sealers.

When it comes to appearance, both your personal preference and the surrounding design have a great impact on your choice. With that being said, concrete sealers can alter the appearance of concrete with sheen and color. For example, if you decide to give your concrete a “wet look” effect, you should probably stick to film-forming sealers. These include acrylics, polyurethanes, epoxies, and others. Whereas, if you choose to keep a natural appearance to your concrete without any additional effects, then your best choice is penetrating sealers.

You can find out more about the types of sealers for concrete, film-forming sealers and penetrating sealers, in the following article, “The Major Types of Sealers for Concrete”.

In addition, if you want to give a color effect to your concrete surface, you should go for colored or tinted concrete sealers. These sealers can be either film-forming or penetrating, however each gives a different color effect. In addition, they are available either as pre-tinted products or as separate sealers and tints or pigments. Nevertheless, it is also important to consider the disadvantages of using colored concrete sealers, which can affect their performance and durability. Mainly, the pigment in colored sealers can form a surface film, thus affecting the adhesion and breathability properties.

You can read more about tinted sealers in the colored concrete sealers section in the following article, “Stamped Concrete Colors: The Ultimate Guide to Coloring Methods”.

Climate and exposure conditions

The climate and exposure conditions can limit your choice towards choosing the best sealers for concrete floors. You should consider the sunlight exposure, moisture condition, temperature range, freeze and thaw cycles, and others.

The climate and exposure conditions can limit your choice towards choosing the best sealers for concrete floors. You should consider the sunlight exposure, moisture condition, temperature range, freeze and thaw cycles, and others.

For example, if you want to apply a concrete sealer to an exterior surface, subjected to sunlight, you should choose a sealer which remains stable in ultra-violet (UV) radiations. Hence, you should avoid choosing epoxy film-forming sealers, which are mostly unstable in UV exposure. In fact, they can start yellowing over time. Nevertheless, some relatively new epoxies are UV resistant to some extent.

In addition, if the moisture content of your concrete increases significantly during water exposure, you should consider this as one of the most important factors. Moisture in concrete can increase in winter for instance, in exterior or slab on ground applications where usually no vapor barrier is used and the water table is high. In fact, in such applications, even if you seal the surface of the concrete floor, the water can find its way from the ground beneath to the top and cause a negative pressure on the sealed surface. Thus, if this is the case, then you should consider the breathability of the concrete sealers.

Why breathability is important here?

In general, if the moisture gets entrapped in concrete which is sealed with a non-breathable film-forming sealer, the moisture and negative pressure can cause various problems. These problems include cloudy surface or hazy look, color variations, efflorescence, and even peeling off. Hence, in order to avoid such issues, you should use a breathable sealer. Usually, most penetrating sealers are breathable, but it is not the same with film-forming sealers. For example, acrylic, which is a film-forming sealer, can be breathable depending on its solids’ content. Whereas most polyurethanes and epoxies are not. Nonetheless, there are relatively new products that are breathable. To elaborate, as the solids’ content in a sealer decreases, its breathability increases, but can negatively affect other properties.

Furthermore, when considering high temperature variations and freeze and thaw cycles, most penetrating sealers perform better than film-forming sealers.

Application

When choosing the best sealers for concrete floors, the application is a major factor. For example, a certain concrete pool deck can have different sealing requirements than a driveway, walkway, garage floor, pool deck, or concrete countertop. In fact, each application is exposed to different controlling factors. For instance, the sealer on a driveway can be exposed to hot tire marks, hot oil, salts and deicers, various chemicals, and high abrasion, unlike that on a walkway.

When choosing the best sealers for concrete floors, the application is a major factor. For example, a certain concrete pool deck can have different sealing requirements than a driveway, walkway, garage floor, pool deck, or concrete countertop. In fact, each application is exposed to different controlling factors. For instance, the sealer on a driveway can be exposed to hot tire marks, hot oil, salts and deicers, various chemicals, and high abrasion, unlike that on a walkway.

In brief, considering some other factors as well, usually the suitable sealers for driveways include penetrating sealers or acrylic film-forming sealers. But, for walkways and sidewalks, penetrating sealers, polyurethane, or acrylic sealers are suitable. For well-designed garage floors, penetrating sealers, epoxy, polyurethane, or acrylic sealers are suitable. For pool decks, penetrating sealers and acrylic film-forming sealers are suitable. Whereas, for countertops, food-grade penetrating sealers as well as food-grade film forming sealers are suitable. However, for each application, some of these sealers perform better than others.

You can find out more about the best performing sealers for different applications in the following article, “Which Concrete Sealers are Best for Patios, Driveways, Pool Decks, and Garages”.

In addition, you should consider the importance of slipperiness of the surface based on the application. For example, sloped driveways and pool decks require low slipperiness and preferably high traction. Hence, if slipperiness is an issue based on your application, penetrating sealers are the best choice. However, you can also use film-forming sealers with an anti-skid additive.

Furthermore, if the surface hardness is of a concern, in applications such as driveways and garages for instance, a surface densifier or hardener is suitable even in conjunction with other sealers, if compatible.

Surface

Another important factor that influences your choice for the best sealers for concrete floors is the surface condition. Is the concrete surface weak, smooth/rough, textured, porous/dense and non-porous? Each condition has a different requirement when it comes to sealing.

Another important factor that influences your choice for the best sealers for concrete floors is the surface condition. Is the concrete surface weak, smooth/rough, textured, porous/dense and non-porous? Each condition has a different requirement when it comes to sealing.

For example, if the surface is weak, you should first consider using a densifying and hardening type of sealer such as silicates. You can then seal the surface with another type of sealer if required. However, the products must be compatible and intended for this use.

If the surface is too smooth and slipperiness is of a concern, you should either consider using a penetrating sealer, or a film-forming sealer with skid-resistant additives.

If the surface has textures and imprints, such as stamped concrete, the density of the textures and stamped concrete patterns also affect your choice of the sealer. Usually, heavy textures and dense patterns provide higher safety and traction. This is beneficial especially in application where slipperiness is of a concern, such as sloped driveways.

In addition, the porosity of the surface not only affects the consumption rate and number of coatings, but also your choice on the type of sealer. For example, if you are using a penetrating sealer, and the surface is very porous, you should use a siloxane-based sealer. Whereas, if the surface is very dense and non-porous, you should use a silane-based sealer. But, for normal surfaces, a silane-siloxane blend or siliconate-based sealers are suitable.

Environmental impact

The environmental impact can also affect your choice on the best sealers for concrete floors. For example, most sealers can be either water-based or solvent-based. The former is typically more environmental friendly especially that it emits little or no volatile organic compound (VOCs).

The environmental impact can also affect your choice on the best sealers for concrete floors. For example, most sealers can be either water-based or solvent-based. The former is typically more environmental friendly especially that it emits little or no volatile organic compound (VOCs).

Cost

The cost of sealers is one of the most important factors that usually influences your choice towards the best sealers for concrete floors. However, most people usually consider the initial cost of the product without taking into account its lifespan or maintenance and long-term costs. For example, choosing a less expensive product that requires re-coating after one year is not better than choosing a slightly more expensive product that can last three years.

The cost of sealers is one of the most important factors that usually influences your choice towards the best sealers for concrete floors. However, most people usually consider the initial cost of the product without taking into account its lifespan or maintenance and long-term costs. For example, choosing a less expensive product that requires re-coating after one year is not better than choosing a slightly more expensive product that can last three years.

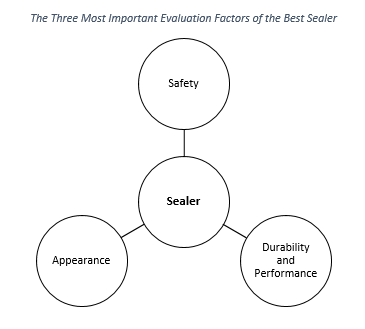

The three most important evaluation factors for the best sealers for concrete floors

Furthermore, for evaluating your choices in order to choose the best sealers for concrete floors, you should consider various factors. The three most important evaluation factors include safety, durability and performance, and appearance.

Safety

Safety is almost always a priority in any application. When talking about safety, you should consider the effect of the product on your health, its effect on the surface such as slipperiness, and its environmental impact.

Safety is almost always a priority in any application. When talking about safety, you should consider the effect of the product on your health, its effect on the surface such as slipperiness, and its environmental impact.

Hence, when evaluating the odds between sealers, safety is an important factor. For example, if you are sealing a kitchen countertop, a safer food-grade sealer is always better. Also, if you are sealing a pool deck for instance, a safer non-slip finish is better than a slippery finish which can be a real hazard. In addition, sealers with little or no VOCs are safer for the both the workers and for the environment.

Durability and performance

The durability and performance of a concrete sealer is a major evaluation factor. Some sealers are much more durable than others and can last longer. In fact, some sealers can last as long as 25 years, or even more. This also affects the long term cost which is crucial. In addition, some sealers are more resistant to certain chemicals, salts, deicers, acids, and weather conditions. This is often essential in applications such as driveways and concrete countertops, which are usually exposed to harsher conditions.

The durability and performance of a concrete sealer is a major evaluation factor. Some sealers are much more durable than others and can last longer. In fact, some sealers can last as long as 25 years, or even more. This also affects the long term cost which is crucial. In addition, some sealers are more resistant to certain chemicals, salts, deicers, acids, and weather conditions. This is often essential in applications such as driveways and concrete countertops, which are usually exposed to harsher conditions.

Appearance

Sealers are usually available in various sheen levels, ranging from no gloss to high gloss. Also, some sealers can be colored or tinted to give an additional decorative touch to the concrete surface. Hence, they have a major effect on the overall appearance of your project. However, each type of sealer and product somehow has its own effect, which may even vary based on the concrete itself. Thus, it is important to have a sealer which matches your aesthetic requirements and expectations on the overall appearance.

Sealers are usually available in various sheen levels, ranging from no gloss to high gloss. Also, some sealers can be colored or tinted to give an additional decorative touch to the concrete surface. Hence, they have a major effect on the overall appearance of your project. However, each type of sealer and product somehow has its own effect, which may even vary based on the concrete itself. Thus, it is important to have a sealer which matches your aesthetic requirements and expectations on the overall appearance.

Conclusion

With the six most important influencing factors, you can easily choose the right sealer for your project in most cases. However, sometimes you may find that you must compromise somewhere to find the right balance. This basically depends on the application and your requirements.

Also, the three most important evaluation factors are often helpful to compare products. This is useful when more than one choice of sealers are suitable for your project.

Example on choosing the best sealers for concrete floors

Let us consider an example of sealing a stamped concrete driveway in a good condition with slight slope. The pattern resembles fieldstone with a slate texture. Also, the owner wants a semi-gloss sheen effect and richer colors. In addition, it is located in an area where the climate is relatively hot, but the temperature slightly drops below freezing in winter.

Let us first start with the six most important factors that influence your choice on the best sealers for concrete floors.

Aesthetics:

Since the owner wants a semi-gloss sheen effect and richer colors, the choice will preferably be a film-forming sealer.

Note: Some penetrating sealers can give richer colors with some gloss to the concrete, however we will stick to film-forming sealers in this example.

Climate and exposure:

The driveway is exposed to sunlight and probably high moisture (since it is an exterior application with no enough data about the moisture related factors). In addition, it is in a relatively hot climate with little to no freeze and thaw cycles in winter. Hence, the sealer should be UV resistant, which narrows our film forming sealer choices to acrylic or polyurethane. Also, they should have a moderate to high breathability. This further narrows our choice to acrylic sealers with low to moderate solids’ content.

Note: Some relatively new polyurethane sealers can be breathable to some extent, however we will stick to acrylic in this example for simplicity.

Application:

Since the application is a driveway, hence it can be exposed to salts, deicers, oil, hot tire marks, abrasion, and various chemicals. Thereby, the acrylic should have somewhat high solids’ content in order to resist these conditions. The higher solid’s content usually provides more cross-linking in the coating, thus making it more resistant to abrasion, chemicals, and hot tire marks.

So, unlike the second factor which called for low to moderate solids’ content, the third factor requires somewhat high solids’ content. Hence, a balanced value should be taken to cover both factors.

Surface:

Since the pattern is a fieldstone with a slate texture, it can provide good traction especially that the slope is low. In addition, acrylic should probably be suitable without the need of a skid-resistant additive.

Environmental impact:

Acrylic is available in water-based and solvent-based forms. Water-based is more environmental-friendly than solvent-based, however will consider both in this example.

Cost:

An acrylic sealer is usually budget friendly considering both its initial and long term costs. It can typically last between 1 and 3 years, averaging about 2 years on a driveway for a normal quality.

Results:

Based on the data acquired from the previous six factors, the suitable sealer is an acrylic film-forming sealer. It should be either high-quality water based or solvent-based, semi-gloss, and with a balanced solids’ content.

Now the decision lies upon weighing the three most important evaluation factors, as stated previously in the second section.

Safety:

Here we should compare the effect of the products on your health, on the slipperiness, and on the environment. Water-based acrylic sealers are mostly safer to use. In addition, they usually do not increase the surface slipperiness as much as solvent-based acrylic sealers do. Also, they are much more environmental-friendly.

Durability and performance:

When it comes to durability and performance, the comparison significantly depends on the products and brands as well. However, typically solvent-based acrylic sealers perform better, but water-based ones are usually cheaper.

Appearance:

In general, solvent-based acrylic sealers enhance the color of concrete more than water-based acrylic sealers do.

As a summary, water-based and solvent-based acrylic sealers are suitable for the given example. Also, by weighing the results, they are somehow comparable. The major difference lies in the appearance effect. However, as a personal opinion, even though the water-based acrylic sealer might perform a little worse than solvent-based ones on the long term, it is always better to prioritize safety and environmental impact.

You can find out more about the best acrylic sealers for stamped concrete in the following article, “The Best Acrylic Sealers for Stamped Concrete: All You Need To Know“.