Definition and Classification of Aggregates

Last updated on March 23rd, 2022

What are aggregates for concrete?

Aggregate is a general term that embraces a wide variety of grained particulate materials with various sizes, physical properties, and chemical compositions.

Aggregates are inert materials which can increase the volume and alter the properties of concrete. In fact, aggregates occupy a large volume in a concrete mixture. Hence, they can influence the fresh properties, hardened properties, mix design, cost, and environmental impact.

Importance of aggregates in concrete

However, the main function of aggregates is to provide an economic volume-filling material. In addition, they may enhance various mixture properties and reduce volume changes, compared to cement paste alone. Hence, a common practice is to use as much aggregates as possible, without violating mix designing standards, in order to decrease the cost and enhance the volume stability of concrete.

The quality of aggregates for concrete matters

However, low quality aggregates may have physical, chemical, and/or thermal problems. Physical problems include swelling and shrinkage, chemical problems include alkali-aggregate reaction, and thermal problems include excessive expansion and contraction. In brief, these problems negatively influence the properties of concrete. Hence, the aggregates must comply with certain standards, such as ASTM C33, for ideal engineering applications. Also, they should be chemically inert, possess proper toughness, hardness, strength, and be free from any impurities.

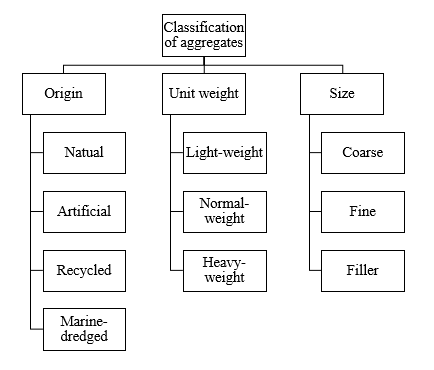

Classification of aggregates for concrete

Aggregates can be mainly classified according to origin, unit weight, and size.

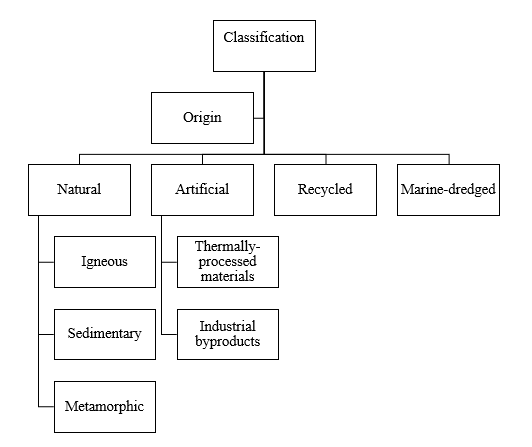

Classification of aggregates according to origin

Based on the classification according to origin, aggregates can be further classified as natural, artificial, recycled, and marine-dredged aggregates.

Natural aggregates for concrete

Natural mineral aggregates include igneous, sedimentary, and metamorphic rocks. This type of aggregates does not require any change in its natural state before its use in concrete, other than washing, grinding, and sieving.

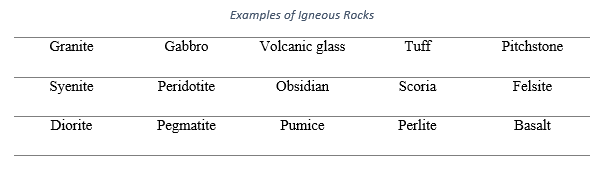

Natural aggregates: Igneous rocks

Igneous rocks form after magma or lava cools and solidifies. Also, these rocks may be in a crystalline form or not. The following table shows examples of igneous rocks.

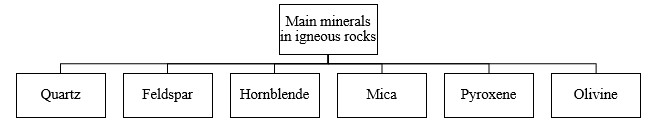

Igneous rocks mainly consist of silica. Besides, minerals like quartz, feldspar, hornblende, mica, pyroxene, and olivine make up over 92% of the common igneous rocks. This type of rocks is an ideal aggregate, especially granite and basalt because of their hardness, strength, and toughness.

Natural aggregates: Sedimentary rocks

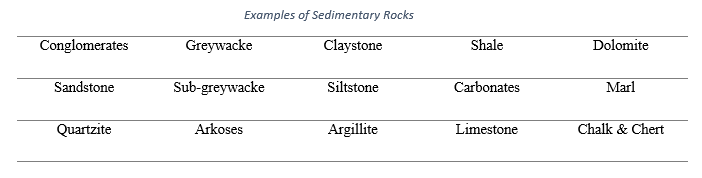

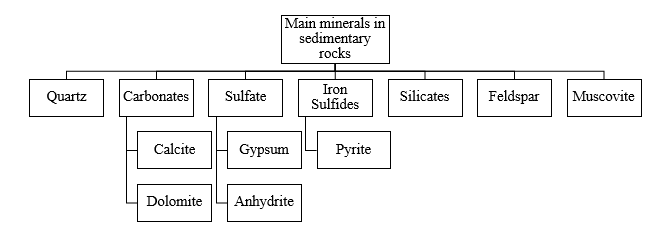

Sedimentary rocks are formed when weathered fragments of other rocks are compressed and cemented together by pressure. The following table shows examples of sedimentary rocks.

Sedimentary rocks mainly consist of quartz, carbonates (such as calcite and dolomite), sulfates (such as gypsum and anhydrite), iron sulfides (such as pyrite), and some silicates, feldspar and muscovite. This type of rocks is relatively cheap since it is abundant near the surface. In addition, it is a very common aggregate in concrete, especially sandstone and limestone. However the quality of sedimentary rocks can vary from poor to excellent aggregates depending on their hardness, density, and absorption.

Natural aggregates: Metamorphic rocks

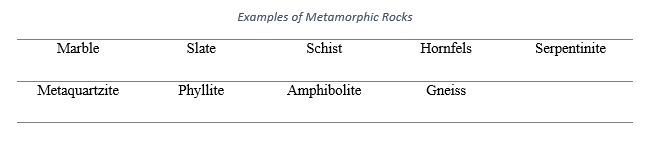

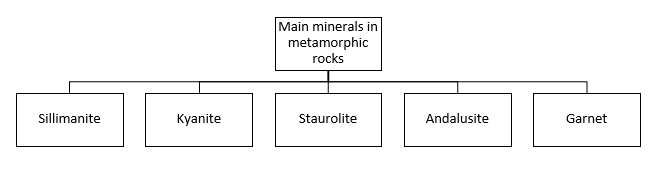

Metamorphic rocks are pre-existing rocks like igneous or sedimentary rocks that have transformed their texture, crystal and mineral structure, or composition. This transformation occurs due to high pressure and temperature under the earth’s crust – metamorphism. The following table shows examples of metamorphic rocks.

Metamorphic rocks mainly consist of minerals such as sillimanite, kyanite, staurolite, andalusite, and some garnet. The quality of this type of rocks can vary from poor to excellent.

Artificial aggregates for concrete

Artificial aggregates, or man-made aggregates, are either a thermally-processed material or an industrial by-product. Thermally processed aggregates include expanded clay, shale, and perlite. These are special aggregates, and are suitable for specific types of concrete, such as light-weight concrete. Whereas aggregates from industrial by-products include cinder and slag in the form of scum.

Recycled concrete aggregate

What is recycled concrete aggregate?

Recycled concrete aggregate is made from crushing concrete. it mainly gains importance because it protects natural resources and lowers the needs and costs of disposal of waste concrete.

The process of recycling concrete is actually simple. It involves crushing, removing steel reinforcements, and breaking concrete into a material with a specific quality and dimensions.

The quality of recycled concrete aggregate is important

Moreover, this recycled concrete aggregate should pass the same tests as other aggregates, since it contains, in addition to the aggregate, hydrated cement which has a lower specific gravity than most aggregates. In addition, recycled concrete aggregate is usually more porous, which would eventually lead to a concrete having higher absorption. Furthermore, recycled concrete aggregate should be treated as a light weight aggregate and in the state of saturated but surface dry.

The use of recycled concrete aggregate in concrete mixtures

A mix that contains a limited amount of recycled concrete aggregate can perform almost equal to a mix with natural aggregates. In general, recycled concrete aggregate can replace up to about thirty percent of coarse aggregates without affecting any of the mechanical properties of the mixture. According to previous studies, as the percent of recycled concrete aggregate exceeds thirty percent, the concrete’s drying shrinkage and creep increase and the tensile strength decreases. However, the compressive strength and freeze-thaw resistance remain almost constant. But, in order to maintain a certain workability and slump, the amount of water reducing additives is slightly increased .

Marine-dredged aggregate

Marine dredged and seashore aggregates are sometimes used in concrete when no better source is available, and in very limited conditions. However, such aggregates contain seashells and salt, thereby a great caution with their usage in concrete is necessary. In addition, due to their angularity, seashells increase the paste demand and may cause voids in concrete. Moreover, marine dredged and seashore aggregates contain chlorides, from salt, which is an undesired compound. Chlorides may cause changes in the setting time, increase the drying shrinkage, cause efflorescence, and results in corrosion of steel reinforcements in concrete. Hence, it is preferred not to use such aggregates in reinforced concrete.

Marine dredged and seashore aggregates are sometimes used in concrete when no better source is available, and in very limited conditions. However, such aggregates contain seashells and salt, thereby a great caution with their usage in concrete is necessary. In addition, due to their angularity, seashells increase the paste demand and may cause voids in concrete. Moreover, marine dredged and seashore aggregates contain chlorides, from salt, which is an undesired compound. Chlorides may cause changes in the setting time, increase the drying shrinkage, cause efflorescence, and results in corrosion of steel reinforcements in concrete. Hence, it is preferred not to use such aggregates in reinforced concrete.

Classification of aggregates according to unit weight

Aggregates can be classified according to unit weight, into three main classes, lightweight, normal weight, and heavy-weight aggregates.

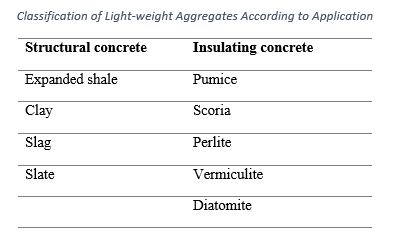

Lightweight aggregates for concrete

Lightweight aggregates have a specific gravity less than 2.4, or bulk density less than 1,120 kg/m3. This type of aggregates is often beneficial in the production lightweight concrete with a density ranging from 1,350 to 1,850 kg/m3, or insulating lightweight concrete with a density ranging from 250 to 1,450 kg/m3. The following table shows examples of lightweight aggregates for concrete, classified according to application.

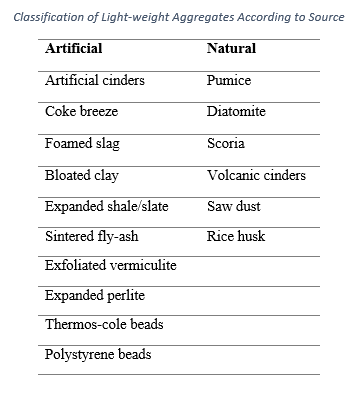

In addition, the following table shows examples of lightweight aggregates for concrete, classified according to source.

Normal-weight aggregates

Normal weight aggregate has a specific gravity ranging from 2.4 to 2.9, and bulk density ranging from 1,520 to 1,680 kg/m3. It is the most commonly used type of aggregate in concrete.

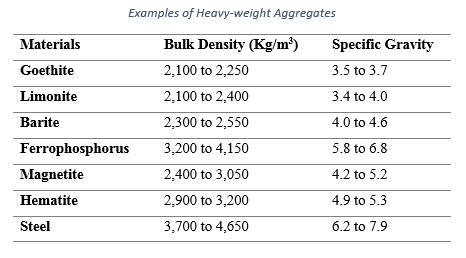

Heavy-weight aggregates

Heavy-weight aggregate has a specific gravity ranging from 3.5 to 7.85, and bulk density more than 2,100 kg/m3. It is usually beneficial in the production of heavy-weight concrete. This type of concrete is mostly used for radiation shielding and counter-weights. Concrete incorporating such type of aggregate mostly has a density ranging from 2,900 to 6,100 kg/m3. The following table shows examples of heavy-weight aggregates.

Classification of aggregates according to size

The classification of aggregates for concrete according to size is the most common classification, where aggregates are classified as coarse or fine.

Coarse aggregates

Coarse aggregates consist of particles that are retained on a sieve with 4.75 millimeters openings (No.4). Generally, the upper size is about 75 millimeters, however particle sizes up to 150 millimeters can be used in mass concrete. In fact, a concrete mix becomes more economical as the aggregate becomes coarser. The surface area of coarse aggregates is less than that of finer aggregates for an equal volume, thus requiring less paste to cover each grain.

Fine aggregates

Fine aggregates have a particle size ranging from 4.75 to 0.075 millimeters. The content of fine aggregates in concrete is generally between 35 and 45% by mass or volume of total aggregate.

Fillers

What are fillers in concrete?

A filler is a material having a particle size less than that of the fine aggregate. According to the European standard EN 13139, filler materials are those that pass through the 63 micrometers sieve (No.230). They are usually chemically inert at normal temperature and pressure. Fillers are produced by crushing rocks to powder, flour, or even dust forms, and are commonly generated from the stone polishing industries.

Benefits of filler materials for concrete

In fact, they are beneficial in filling gaps between particles, thus reducing the binder content in concrete. The function of fillers is mainly related to their particle size and shape. When properly used, fillers can enhance the particle packing density of a mixture, and thereby influencing the fresh and hardened properties of concrete.

Hazards of some filler materials

These by-products are mostly hazardous to human beings since they are easily inhaled and can be airborne.

Classification and types of fillers for concrete

Common calcium-carbonate-based fillers include pure calcium carbonate powder, limestone dust, ground chalk, and marble dust. Whereas, common silicon-dioxide-based fillers include quartz powder, silica flour, and granite powder.

Conclusion

Aggregates are an important constituent in concrete, which occupy a relatively large volume. They can be classified according to origin, unit weight, or size. In addition, the quality of aggregates is essential since it can influence the overall performance and durability of concrete. Thus, aggregates should meet certain standards such as the ASTM C33.

Bibliography

- ACI (2002). ACI PRC-555-01: Removal and Reuse of Hardened Concrete. American Concrete Institute.

- ACI Committee. (2007). Aggregates for Concrete.

- Langer, W., & Knepper, D. (1995). Geological Characterization of Natural Aggregate. S. Geological Survey.

- Odimegwu, T., Zakaria, I., Abood, M., & Ibearugbulem, O. (2018). The Use of Industrial Wastes as Filler in Concrete/Mortar: A Critical Review. Journal of Engineering and Applied Sciences, 13(15), 5987-5996.

- PCA (2020, March 22). Recycled Aggregates.

- PCA (2011). Design and Control of Concrete Mixtures. Portland Cement Association.

- Vakhshouri, B., & Nejadi, S. (2017). Review on the mixture design and mechanical properties of the lightweight concrete containing expanded polystyrene beads. Australian Journal of Structural Engineering.