Definition and Classification of Admixtures for Concrete

Last updated on March 23rd, 2022

The definition of admixture in concrete

Admixtures can be defined as the constituents other than the binder, filler, water, and reinforcements in concrete. They are commonly available either in a liquid form or in a powder form. Besides, their efficacy depends on several factors including mix proportions, materials, and weathering conditions. Mainly, their purpose is to:

- Alter the properties of fresh concrete during mixing, transporting, casting, and/or curing.

- Enhance the properties and/or durability of hardened concrete.

- Or simply to reduce cost.

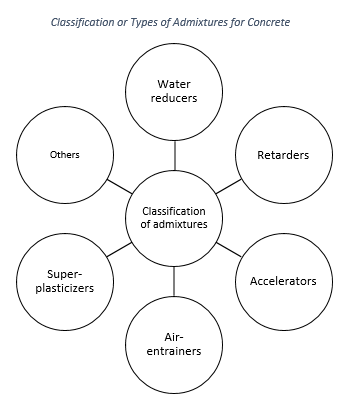

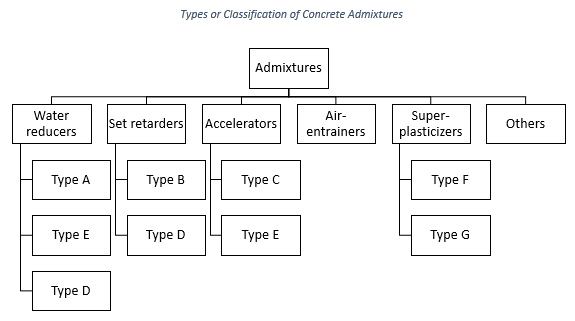

Classification of admixtures

Admixtures are primarily classified, based on their function, into five major classes, water reducing, retarding, accelerating, air-entraining, and super plasticizing. In addition, a specialty class contains various types of other minor admixtures.

1) Water-reducers

Water reducing admixtures are chemicals that reduce the amount of required water in a concrete mixture for a fixed slump. Thereby, water reducers have various benefits such as:

- Enhancing the strength for a fixed slump.

- Increasing the workability for a fixed water content.

- Reducing the cement content for a fixed strength.

- Reducing cost.

- Or enhancing the surface appearance of flat concrete.

Water reducing admixtures consist of lignosulfonate, alkyl aryl sulfonates, sulfonate melamine formaldehyde, sulfonate naphthalene formaldehyde, resin sulfonate, molasses, humic aid, hydro-carboxylic acids, or others. In fact, this type of admixtures acts based on either the mechanism of electrostatic repulsion or that of steric stabilization, depending on its composition.

Types of water reducing admixtures

In addition, water reducers can be classified, based on their performance, into normal and mid-range water reducers. The former has up to 10% water reducing capacity, while the latter has up to 15%. Furthermore, ASTM C494 separates water reducers into three types, A, E, or D. Type A is the basic water reducer, while type E is modified with an accelerator, and type D is modified with a retarder.

2) Set-retarding admixtures

Retarding admixtures, or set retarders, are chemicals that slow down the setting rate of concrete and are usually used in hot weather concreting. In such weather, retarders counteract the effect of quick setting due to high temperatures. In fact, they extend the open time of fresh concrete.

Set-retarding admixtures mainly consist of calcium sulfate, gypsum, sugars, carbohydrates, salts from acids, soluble zinc, soluble borates, or others. They act based on several mechanisms including adsorption, nucleation, complexation, and precipitation.

Types of set retarding admixtures

Retarders can be classified, according to origin, into organic and chemical. Organic retarders include lignosulphonates, phosphonates, salts from acids, and sugars. Whereas chemical retarders include borates and zinc. Also, retarders can be classified according to performance, into type B or D. Type B is a basic set retarder, whereas type D is a set-retarder and water reducer.

3) Accelerators

Accelerating admixtures are chemicals that decrease the setting time and increase the hardening rate of concrete. They are usually used in applications where short curing period or early formwork removal is required, and in urgent repairs or cold weather concreting applications.

Accelerators mainly consist of nitrite, nitrate, thiocyanate, formate, tri-ethanol-amine, calcium chloride, or others. However, for the calcium chloride based accelerator, it is important to limit its quantity in concrete. In fact, the main disadvantage of calcium chloride is that it causes corrosion of steel reinforcements.

Types of set accelerating admixtures

Also, accelerators can be classified into type C and type E. Type C is the basic accelerator, whereas type E has both accelerating and water-reducing effects.

4) Air-entraining admixtures

Air-entraining admixtures are chemicals that mainly enhance the durability of concrete, especially its freeze and thaw resistance. In addition, it also improves the workability and the resistance to segregation and bleeding. However, air-entrainers can reduce the strength of concrete. In general, as the amount of air increases by 1%, the strength decreases by about 5%.

The mode of action of this type of admixtures is that it forms uniformly distributed tiny air bubbles inside concrete.

Air entrainers mainly monist of natural wood resins, animal fats, vegetable fats, natural oil, alkali salts, polyethylene oxide polymers, neutralized vinsol resins, sulfonated compounds, or others.

5) Super plasticizing admixtures

Super plasticizing admixtures, or high range water reducing agents, are chemicals that reduce the amount of required water for a fixed slump more than normal or mid-range water reducers do. In general, the water reduction capacity for most super-plasticizers ranges from 12 to 30%. However the new generation or third generation super plasticizing admixtures have a water reduction capacity up to 40%.

High range water reducers usually consist of lignosulphonates, sulfonated melamine formaldehyde, sulfonated naphthalene formaldehyde, or poly-carboxylic acid. In fact, they can be classified into generations based on their composition. For example, lignosulfonates are the first generation, sulfonated formaldehyde condensates are the second generation, and poly-carboxylates and acrylates are the third generation high range water reducers.

Types of super plasticizing admixtures

Super plasticizing admixtures can be also classified into two types, F and G. Type F is a basic high range water reducer, whereas type G has also a retarding effect.

Specialty admixtures

Specialty admixtures include various chemicals such as air detraining agents, damp proofers, alkali-aggregate and alkali-silica expansion inhibitors, shrinkage reducers, anti washout agents, corrosion inhibitors, bonding agents, hydration stabilizers, viscosity modifying agents, viscosity enhancing agents, pumping aids, fungicidal or insecticidal agents, permeability reducers, foaming agents, expanding agents, anti-freeze agents, colors, and dyes.

Summary of the types or classification of admixtures for concrete

Bibliography

- Chakkamalayath, J., Santhanam, M., & Gettu, R. (2011). Cement-superplasticiser compatibility – Issues and challenges. Indian Concrete journal, 48-60.

- PCA (2011). Design and Control of Concrete Mixtures. Portland Cement Association.

- PCA (2020, March 27). Chemical Admixtures. Retrieved from Portland Cement Association, America’s Cement Manufacturers.

- Rahman, F. U. (2020, March 28). Retarders for Concrete – Mechanism, Types and Effects on Properties.

- Zhang, H. (2014). Building Materials in Civil Engineering. In Woodhead Publishing Series in Civil and Structural Engineering (pp. 81-149). Woodhead Publishing Series in Civil and Structural Engineering.

- Jamal, H. (2017, March 18). Types of Admixtures of Concrete & Cement.