Concrete Slump: Meet the Standards

Last updated on February 28th, 2022

What is concrete slump?

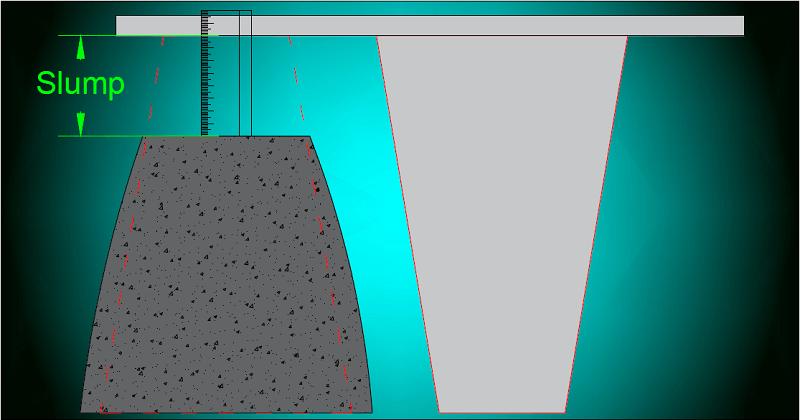

Slump is a measurement of consistency of fresh, plastic, and cohesive concrete. In essence, it is a workability quantification that checks the consistency of a batch and defines how workable a certain concrete mixture is. Specifically, it measures how much a fresh mixture, placed in a cone-shaped mold of certain dimensions, “vertically slumps” after the removal of the mold. Hence, the higher the slump, the more workable the concrete is.

The importance of slump in concrete

Slump is one of the most commonly used workability parameters. It is often considered when proportioning or designing mixtures, when specifying concrete, and when ordering it. Besides, slump can be easily measured on-site and in the laboratory.

How to measure concrete slump?

The slump of concrete can be determined in accordance with standard test methods. These mainly involve filling a cone-shaped mold of specific dimensions with fresh concrete, then measuring the subsidence after the removal of the mold.

Standards for concrete slump measurement

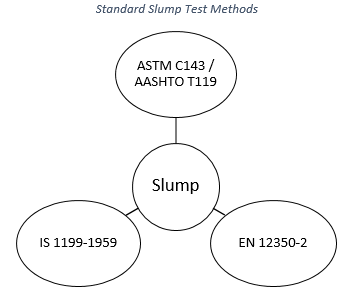

The main standard test methods include the following:

- American: American Standards for Testing and Materials, ASTM C143 – Standard Test Method for Slump of Hydraulic Cement Concrete.

- American: American Association of State Highway and Transportation Officials, AASHTO T119 – Standard Method of Test for Slump of Hydraulic Cement Concrete.

- European: European Norm, EN 12350-2 – Testing Fresh Concrete – Part 2: Slump Test.

- Indian: Indian standard, IS 1199-1959 – Methods of Sampling and Analysis of Concrete.

In fact, these methods are basically similar to each other with only minor differences.

Comparison in the slump test procedures between standards

On one hand, as for the main similarities, ASTM C143, AASHTO T119, EN 12350-2, and IS 1199-1959 all use cone-shaped molds of the same dimensions, same rod diameter, and the number of strokes with the tamping rod. Thereby, their basics are quite the same. In addition, it is important to note that the ASTM C143 and the AASHTO T119 are basically similar.

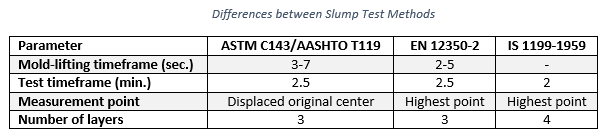

On the other hand, there are some minor differences when it comes to the timeframe for lifting the mold, timeframe for the test completion, point of measurement, acceptance of the results, and number of placement layers.

First, ASTM C143 and AASHTO T119 specify a 5-second timeframe with a tolerance of 2 seconds to completely lift the mold. Hence, the acceptable timeframe is 3-7 seconds. Whereas, EN 12350-2 specifies a window of 2-5 seconds, and IS 1199-1959 does not address this timeframe.

Second, ASTM, AASHTO, and EN specify that the test should be completed, from the time of filling the mold till its removal, uninterruptedly within 2.5 minutes. Whereas, this value is only 2 minutes in the IS standard.

Third, ASTM and AASHTO consider the slump measurement to the displaced original center of the top surface. Whereas, EN and IS consider the highest point measurement.

Fourth, ASTM, AASHTO, and EN state that if a portion of concrete shears off the pile, in two consecutive tests, then the results should be disregarded since the mixture does not have the required plasticity and cohesiveness for the test to be applicable. Whereas, the IS still considers the second measurement while noting that the specimen had sheared off.

Fifth, ASTM, ASHTO, and EN consider the placement of concrete on three layers. Whereas, the IS considers it on 4 layers.

Evaluating the test results

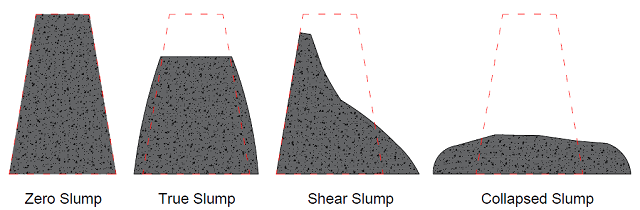

The slump test can have four possible outcomes, zero slump, true slump, shear off slump, or collapsed slump.

- Zero slump: The mixture reserves its shape after the removal of the mold, with a slump less than 1/4” (6mm). This indicates that the mixture is stiff and dry. Such mixtures are usually used in applications such as pavements with roller-compacted concrete.

- True slump: The mixture “slump down” but somewhat retains its cone shape after the removal of the mold. This shows that the mixture is plastic and cohesive enough for this test to be applicable.

- Shear off slump: The mixture largely slumps to one side in an inclined plane. This indicates that it lacks cohesiveness. However, when this type of slump occurs, the standards state that the slump test should be repeated. In addition, if the second test also results in a shear off slump, then the mixture lacks cohesiveness and plasticity for the test to be applicable.

- Collapsed slump: The mixture largely slumps down and completely loses its original cone shape. This indicates that the mixture is highly workable but lacks the plasticity for this test to be applicable. Thereby, in this case other tests are more suitable, for example flow test.

Choosing the slump

For choosing the slump, we will be referring to three standards:

- American: American Concrete Institute, ACI 211.1 – Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete.

- British: British Standards, BS 8500 – Concrete – Complementary British Standard to EN 206.

- Indian: Indian standard, IS 456 – Plain and Reinforced Concrete – Code of Practice.

The ACI 211.1 provides a table, specifically table 6.3.1 (imperial) or A1.5.3.1 (metric), which recommends slump ranges based on the application.

The BS 8500 classifies slump ranges into five classes, S1 to S5, in which they slightly vary based on the sampling method. However, unlike the ACI 211.1 and IS 456, this standard does not provide guidance for the selection of slump based on the type of construction.

The IS 456, similar to the ACI 211.91, also provides a table, specifically in section 7 of IS 456-2000, for the selection of the slump range based on the application.

What influences the slump of concrete?

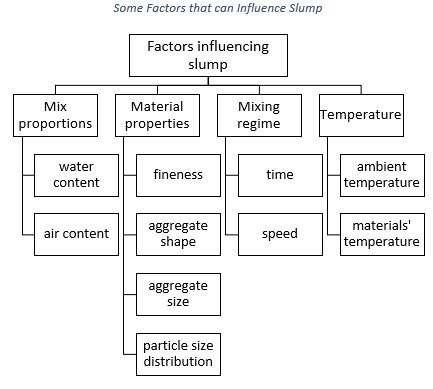

There are numerous factors that can influence the slump of concrete. Basically, the above figure illustrates some of these factors which are related to the mix proportions, properties of constituent materials, mixing regime, and temperature.

Mix proportions

The mix design and proportions of the materials have a major effect on the slump. For example, the water content or air content are directly proportional to concrete slump. To illustrate, as the water or air content increase in a certain mixture, the slump increases, and vice-versa.

Properties of constituent materials

Also, the properties of constituent materials can have a significant influence the slump. These include the fineness of cement or other binding materials, aggregate shape and size, and particle size distribution.

For instance, as the fineness of binders increases in a certain mixture, the slump generally decreases.

In addition, the shape and size of aggregates play a major role. For example, round aggregates usually increase the slump, whereas sharp-edged aggregates can decrease it. Also, larger aggregates have a smaller surface contact area, which can increase the slump.

Mixing regime

The mixing regime can also affect the slump of concrete. For example, vigorous mixing can entrap air, which we previously addressed its effect on the slump, however it can increase the temperature of the mixture.

Temperature

Likewise, temperature is also a major factor. In brief, as the temperature of air, ingredients, or the mixture increases, the slump generally decreases.

Concrete slump vs strength

The relation between concrete slump and strength is generally inversely proportional, when the effect of admixtures is disregarded. This is mainly due to the fact that the slump and water content are directly proportional for a given mixture. Besides, the ASTM C143 states that these relationships are generally correct in laboratory conditions, but not clear and consistent under field conditions. However, this can be explained since there is not as much control on various conditions in the field as in the laboratory. To illustrate, a mixture with higher slump can be easier to place and compact than a similar mixture with lower slump, which can explain the inconsistency of some field results, for example.