Concrete Mix Proportioning Calculator (IS Code) Metric

This concrete mix proportioning calculator performs calculations based on the IS codes, standards, and guidelines. The user can simply input the essential data, and this calculator does all the work, it is as simple as that!

Note:

This concrete mix proportioning calculator requires data input in metric units. All you need to do is to fill the fields on the first page, and hit the blue “next” button at the bottom left side to check the results. In addition, you can read the informative notes or instructions next to various fields to help you better understand the input requirements.

This tool performs calculations according to a very precise and scientific procedure, based on the IS standard. In brief, the user can enter the input on the first page, in a very accurate yet a simple manner.

After the user fills the input data, the concrete mix proportioning calculator performs all the necessary calculations to show the results on the next page. In general, such calculations, when performed manually, can be time consuming. Also, they require the user to refer back to standards and guidelines with various tables and equations. However, with this concrete calculator, you can do most of the preliminary work in just a couple of minutes, literally! Thereby, all the essential data is built in this calculator to give the best and most accurate results, notes, and checks.

Moreover, the third page presents the basic calculation parameters. These are important to check and understand the calculations behind the results. In addition, this page is essential in interpreting and evaluating not only the results, but also the input. Thereby, if the user needs to make any adjustments or to simply check with their manual calculations or procedure, this page provides valuable data.

What concrete grades are covered in this calculator?

With this concrete calculator, you can easily design a variety of mixtures that conform to the IS code in no time. You can determine the mix proportions for M10, M15, M20, M25, M30, M35, M40, M45, M50, M55, M60, and M65 grades of concrete. In addition, this tool is very flexible with the data input, and covers a wide range of materials and properties.

Note

However, it is important to mention that although this concrete mix proportioning calculator is simple, the user must have an engineering background to properly input the data and understand and evaluate the results. Nevertheless, we included simple notes or instructions to various fields so that the user can easily understand the requirements or refer back to a certain parts of the IS code.

For further information about the concrete mix proportioning method following the IS code, check out the Concrete Mix Proportioning (Ratio & Design) per IS code article.

Before getting into the step by step procedure of using this concrete calculator, it is important that the user knows the basic data requirements prior to any mix proportioning. This data includes material availability, material properties, specifications, environmental conditions, exposure, placement method, etc…. In addition, the user should have, not only an engineering background, but also experience with the IS code. In brief, the typical procedure of using this tool is as follows.

Step 1: General data input

The first page or the data input page is mainly consists of two categories, general data input and constituent material properties.

Selecting the grade of concrete

The first field is a drop-down menu for the grade of concrete, including M10, M15, M20, M25, M30, M35, M40, M45, M50, M55, M60, and M65. In this notation, the letter M stands for ‘Mix’, and the number following the letter M is the compressive strength at 28 days, on 150 mm cubes. Thereby, when choosing M30 for example, it means that you are aiming for a concrete with a compressive strength of 30 MPa at 28 days.

Selecting the required slump

The second field is the slump of concrete, in millimeters. The most common slump values range between 50 and 120 mm, however lower and higher values are also applicable depending on the application and requirements. Also, in this field, the user should enter the value without any letters or units.

Selecting the exposure condition

The third field is a drop-down menu for the exposure conditions of concrete, including mild, moderate, severe, very severe, and extreme. These five categories are addressed in the IS 456-2000 Table 3.

Selecting the type of concrete

The fourth field is also a drop-down menu, where the user can chooses the the type of concrete, including plain and reinforced.

Selecting the placement method & reinforcement condition

The fifth and sixth fields are also drop-down menus, where the user selects whether the placement method is by pump, and whether the reinforcements are congested or not, respectively.

Selecting the method of calculating the standard deviation

The seventh field is a menu for selecting the method of determining the standard deviation, including ‘Assume the Standard Deviation’ and ‘Use Specified Standard Deviation’. In brief, if the standard deviation is unavailable yet, which is the common procedure for new mixtures, select the first option. In this case, the concrete mix proportioning calculator assumes the standard deviation based on the code. Whereas, if the standard deviation is known, calculated for at least 30 specimens, select the second option and proceed to enter its value in the next field.

Entering the value of standard deviation

The eighth field is an unlocked field in case the user selects ‘Use Specified Standard Deviation’ in the previous field. The user should enter the value of the standard deviation in MPa.

Select the exposure condition to sulfate attacks

The ninth and tenth field are also drop-down menus, regarding the exposure conditions to sulfate attacks. In the first field, the user simply selects whether the concrete is subject to sulfate attacks or not. If yes, the user then has to select the class of exposure to sulfate attacks including five classes as per the IS code.

Step 2: Material properties input

On the first page, the data input page, the second section addresses the constituent material properties. The materials include cement, mineral admixtures, coarse and fine aggregates, and admixtures.

Cement

First, the user should identify the type of cement and its specific gravity. The types of cement include OPC 33, OPC 43, OPC 53, PPC, and PSC. OPC stands for ordinary Portland cement, followed by the strength class of cement. PPC stands for Portland pozzolana cement and PSC stands for Portland slag cement.

Mineral Admixtures

Second, the user should identify the type of mineral admixtures, or supplementary cementitious materials, if any, its replacement percentage, and its specific gravity. The types of mineral admixtures include fly ash, slag, and silica fume. In case the user is using a mineral admixture, it is important to provide its replacement percentage. The replacement percentage is its content of the total cementitious materials by weight. For instance, if the mixture includes 20% fly ash by the total weight of cementitious materials, the user should enter the value 20 in this field.

Coarse aggregate

Third, the user should fill five essential fields about the properties of the coarse aggregate. These fields include the nominal maximum aggregate size, type, specific gravity, moisture content, and water absorption. The first field includes the nominal maximum aggregate sizes available, which are 10, 20, and 40 mm. The second field includes four different types or particle shapes in particular, such as angular, sub-angular, gravel with crushed particles, and rounded gravel. The other three fields include the specific gravity in SSD condition, and the moisture and absorption percentages.

Fine aggregate

Fourth, the user should also fill five important fields about the properties of the fine aggregate. These fields include the source, grading zone, specific gravity, moisture content, and water absorption. Besides, the source of fine aggregates include natural, crushed stone, manufactured, and mixed. In addition, the grading zone includes the four main grading zones as per the IS code.

Admixtures (water-reducer)

Fifth, the user selects whether the mixture incorporates a water reducing admixture or not. If it does, the user should provide the dosage, as percentage by weight of the cementitious materials. Also, the user should provide the water reduction capacity at the specified dosage. In general, these data are best obtained by testing. And finally, the user should enter the specific gravity of the water reducer.

Step 3: View the results and mix proportions

After the user enters all the essential data in the first page, they can check the results by hitting the ‘next’ button at the bottom left side of the tool. In fact, this concrete mix proportioning calculator presents two mix proportions in separate columns. The first mix proportions column considers a saturated but surface dry (SSD) condition of aggregates. Whereas the second mix proportions column considers the actual condition of the aggregates.

In addition, this calculator shows a ‘checks and notes’ section on the same page. This section is very important in understanding the major parameters of your concrete mixture. Specifically, the checks include a check on the grade of concrete, maximum cementitious content, approximate air content, and governing w/c. Moreover, this concrete mix proportioning calculator presents seven essential notes about various parameters of your concrete mix.

Step 4: View the concrete mix proportioning calculation parameters

After viewing the results, checks, and notes, the user can view various calculation parameters on the next page. This page presents the important calculation steps and procedure, so that the user can better understand and evaluate the results. In addition, this page is essential for comparing with manual calculations or checking the accuracy of the results. Moreover, engineers or mix design formulators usually use such data to fill out their custom reports.

Step 5: Check the results

Actually, this is the most important step that every user should perform. No matter how advanced and accurate a concrete mix proportioning calculator or any other tool is, it is always essential for the user to interpret and evaluate the results. Generally, if the results are not logic, the first step is to check the notes. In the notes section, you can easily determine where the problem is. In most cases, a wrong input leads to inaccurate or misleading results. For instance, entering a specific gravity of 315 instead of 3.15 for cement will certainly lead to non-logical results. In addition, in case a user finds any flaw or defect in this calculator, or has any question, we highly recommend to inform us by an email.

Example

A concrete of grade M30 is required for a reinforced concrete slab on grade, with contested reinforcement. The slump should be about 75mm, and the concrete will be pumped to the location. The exposure conditions based on the IS 456-2000 is “moderate”.

In addition, the cement is OPC43 with a specific gravity of 3.15.

Also, fly ash with a specific gravity of 2.20 will be used as a partial replacement of cement at 15% by weight of the total cementitious materials.

The coarse aggregate is angular with a maximum nominal size of 20mm, having a specific gravity of 2.75, moisture content of 2%, and absorption of 3%.

The fine aggregate consists of zone II natural sand with a specific gravity of 2.65, moisture content of 6%, and absorption of 2%.

In addition, a water reducer will be used at a 1.2% by weight of cementitious materials, that will have a water reduction capacity of about 20%. Besides, it has a specific gravity of 1.1.Solution

Data input

The first page in this concrete mix proportioning calculator consists of two main sections, the general data input and properties of constituent materials.

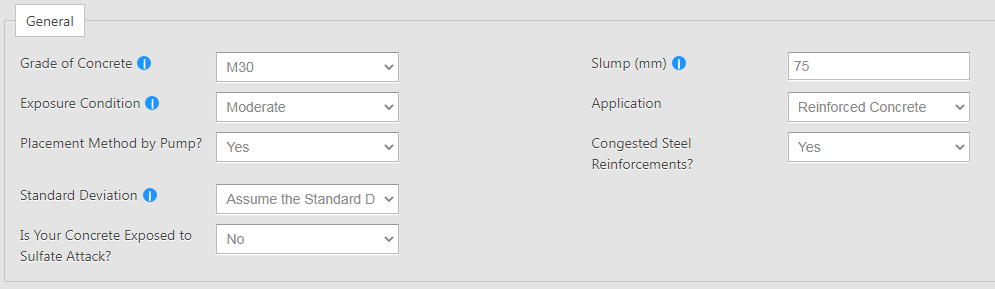

1. General data input

This section includes the grade of concrete, slump, exposure condition, application, placement method, standard deviation, sulfate exposure. Based on the given data, the input is as follows:

- Grade of Concrete = M30.

- Slump = 75mm.

- Exposure Condition = Moderate.

- Application = Reinforced Concrete.

- Placement Method by Pump = Yes.

- Congested Steel = Yes.

- Standard Deviation = Assume the Standard Deviation.

- Is Your Concrete Exposed to Sulfate Attack = No.

2. Material properties

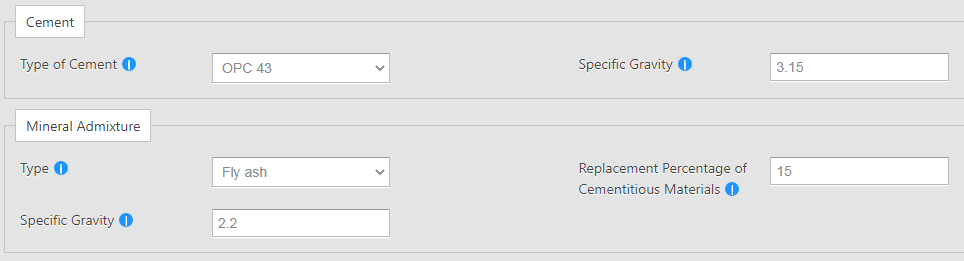

The second section includes data input about the material properties of cement, mineral admixtures, aggregates, and admixtures as follows:

- Type of Cement = OPC43.

- Specific Gravity of Cement = 3.15.

- Type of Mineral Admixture = Fly ash.

- Specific Gravity of the Mineral Admixture = 2.2.

- Replacement Percentage of Cementitious Materials = 15.

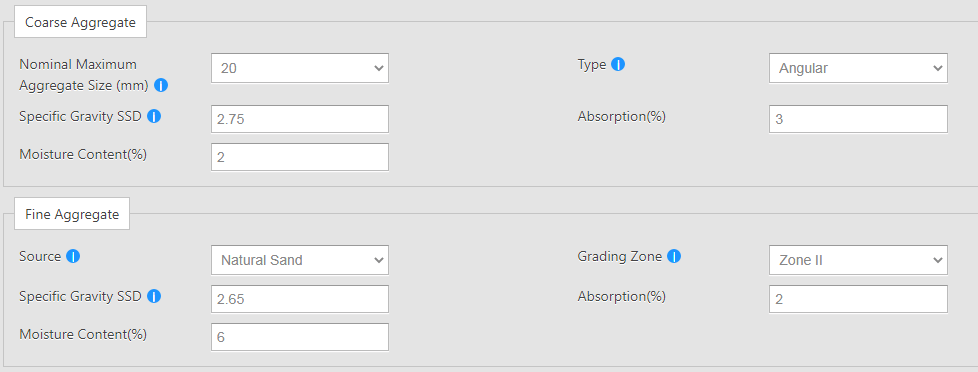

- Nominal Maximum Aggregate Size (mm) = 20.

- Type = Angular.

- Specific Gravity of coarse aggregates = 2.75.

- Absorption(%) of coarse aggregates = 3.

- Moisture Content(%) of coarse aggregates = 2.

- Source of fine aggregates = Natural Sand.

- Grading Zone = Zone II.

- Specific Gravity of fine aggregates = 2.65.

- Absorption(%) of fine aggregates = 2.

- Moisture Content(%) of fine aggregates = 6.

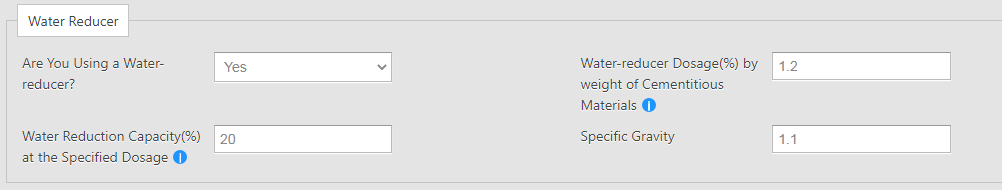

- Are you using a water reducer = Yes.

- Dosage(%) by Weight Of Cementitious Materials of the water reducing admixture = 1.2.

- Water Reduction Capacity(%) at the Specified Dosage = 20.

- Specific Gravity of the water reducing admixture = 1.1.

Results

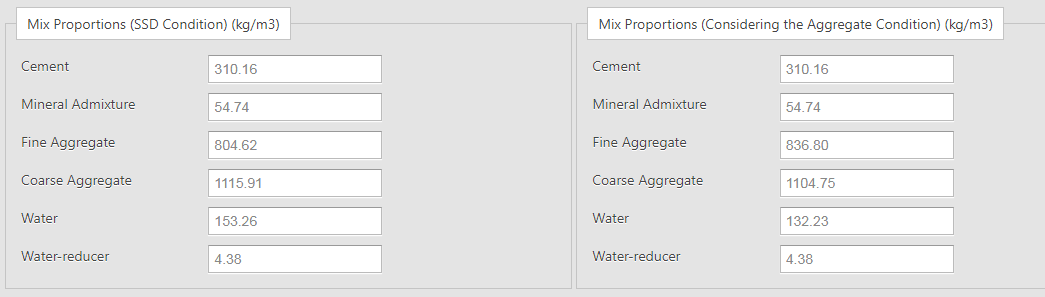

Based on our input on the first page, the second page provides the results. In fact, this page consists of two sections as well, the mix proportions and the checks and notes. The following image shows the mix proportions for this example.

These proportions are in Kg/m3 for SSD condition of aggregates on the left hand side and considering the condition of aggregates on the right hand side.

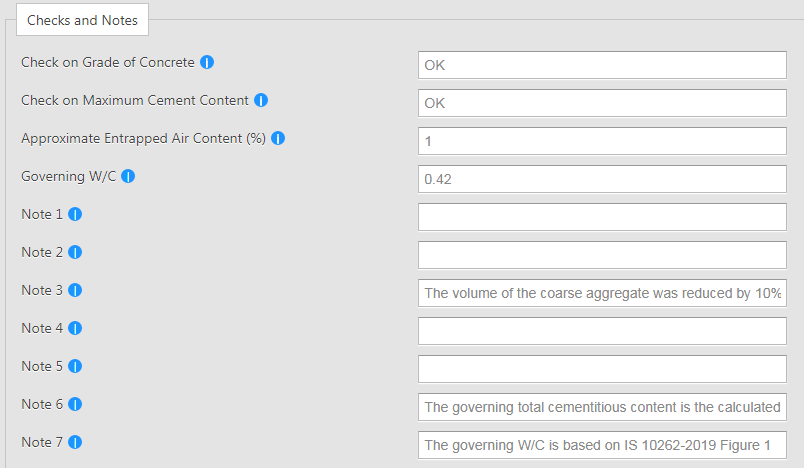

Checks and notes

The second section on this page include the important checks and notes. The concrete mix proportioning calculator provides checks on the grade of concrete and the maximum cement content. In addition, it informs the user about approximate entrapped air and governing water to cement ratio. Furthermore, it provides the user with seven essential notes, which we will cover later on.

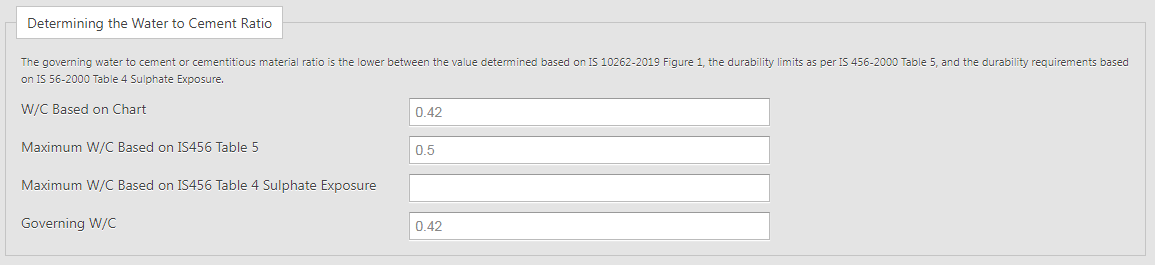

In this example, the grade of concrete, M30, meets the minimum requirements of the durability check based on the IS 456-2000 Table 5. Thereby, the first field shows “OK”. Also, the cement content does not exceed the allowable limits set by the IS 456-2000 Section 8.2.4.2. Hence, the second field also shows “OK”. Furthermore, this section shows us that the approximate entrapped air content is 1%, and that the governing water to cement ratio is 0.42.

Next, we will check the seven main notes as follows.

Note 1

This field informs the user about some considerations when the content of fly ash is in excess of 20%. However, we used only 15%, and thereby the field is left empty.

Note 2

This note informs the user about some considerations when using sand of zone IV in reinforced concrete. However, we used sand of zone II, and hence the field is left empty.

Note 3

The third note shows us that the volume of the coarse aggregate was reduced by 10% since we selected congested steel reinforcements and a placement method by pump, based on Section 5.5.2 from IS 10262-2019.

Note 4

The fourth note informs us in case the type of sand has an effect on the volume of individual aggregate types, based on IS 10262-2019 Table 5 Note 3. However, this field is left empty since we selected natural sand.

Note 5

The fifth note warns us in case the type of cement is inadequate. However, this field is left empty, thus there is no restriction on the selected type of cement.

Note 6

The sixth note informs us that the governing total cementitious content is the calculated value based on IS 10262-2019 Figure 1.

Note 7

The seventh note informs us that the governing W/C is based on IS 10262-2019 Figure 1.

Calculation parameters

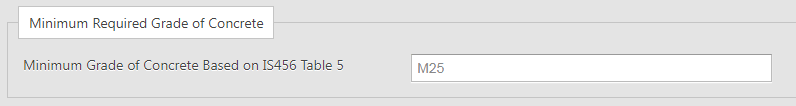

The minimum required grade of concrete

In this concrete mix proportioning calculator, the third page shows various calculation parameters. For this example, the m

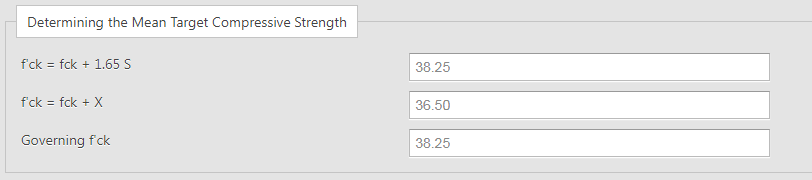

The mean target compressive strength

The mean target compressive strength is determined based on the higher value between two equations. In this example, the governing target compressive strength is 38.25 MPa.

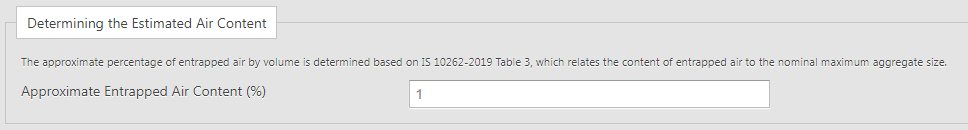

The approximate entrapped air content

This field shows that the approximate entrapped air content is 1%.

The water to cement ratio

In this concrete mix proportioning calculator, the governing water to cement ratio is determined based on the least value between three limits. Here, the governing w/c is 0.42.

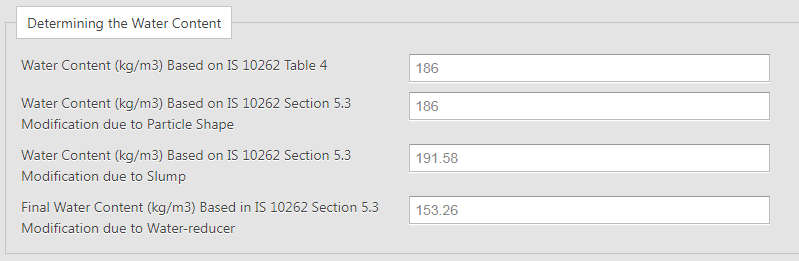

The water content

Determining the water content relies on four major factors. First, the approximate water content relies on IS 10262 Table 4, which is 186 kg/m3 in this example. Second, this value is subject to modification due to the particle shape of the aggregates, but remains with no modification in this example since we selected angular aggregates. Third, this value is then subject to modification due to slump, increasing to 191.58 kg/m3. Fourth, the final modification depends on the incorporation of water reducers, decreasing to 153.26 kg/m3.

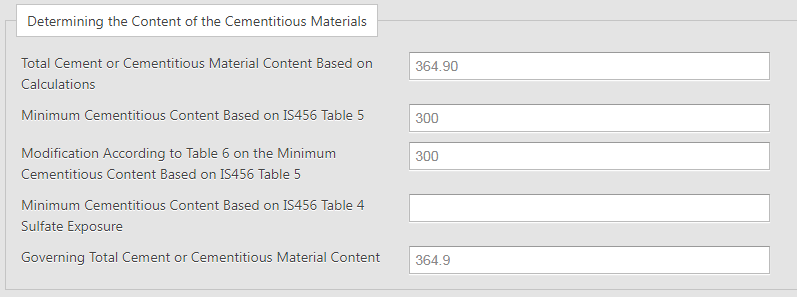

The content of cementitious materials

The content of cementitious materials is the highest between four values. First, this content is determined considering the water content and the w/c. Briefly, the water content is 153.26 kg/m3, and the w/c is 0.42, hence these yield a cementitious content of 153.26/0.42 = 364.90 kg/m3. Then, this value is compared to the minimum cementitious content requirements based on the IS standard. In this example, the governing content is 364.90 kg/m3.

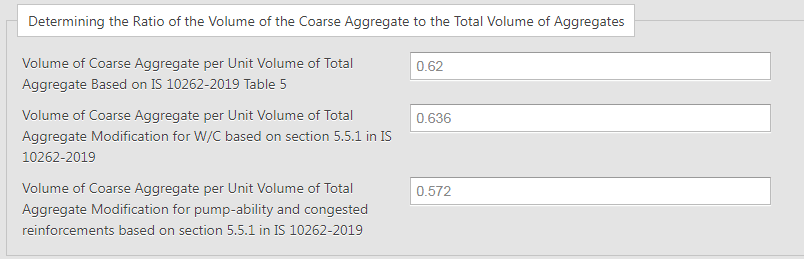

The ratio of the volume of coarse aggregates to the total aggregate volume

This part of the concrete mix proportioning calculator informs the user about the ratio of the volume of the coarse aggregate to the total aggregate volume. In addition, the calculator performs modifications due to the w/c and placement methods. Here, the final ratio is 0.572.

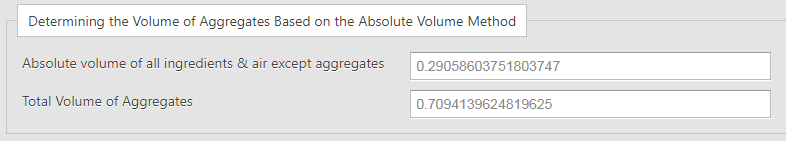

The volume aggregates

This section consists of two fields, the absolute volume of all the ingredients and air in the mix, except the volume of aggregates, and the total volume of aggregate. Simply, the second field is equal to the unit volume (1m3) minus the first field.

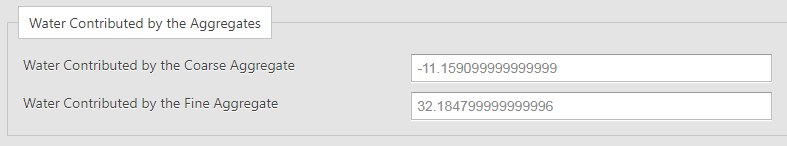

The water contributed by the aggregates

In this example, the coarse aggregates contributed to negative 11.16 kg (since the absorption is higher than the moisture content) of water per one cubic meter of concrete. Whereas, the fine aggregates contributed to negative 32.18 kg of water per one cubic meter of concrete.

This calculator is based on the IS 456-2000 and IS 10262-2019.