The Major Types of Sealers for Concrete

Last updated on March 23rd, 2022

The different types of concrete sealers

Concrete sealers and can be classified, according to their working mechanism, into two types: surface film-forming or topical sealers and penetrating sealers.

Topical sealers

Film-forming or topical concrete sealers, as their name implies, are compounds that form a membrane on the surface of concrete. This type of concrete sealers usually slightly darkens the color of the surface and gives it a shiny look or a “wet look”. In addition, it is usually available in different levels of gloss.

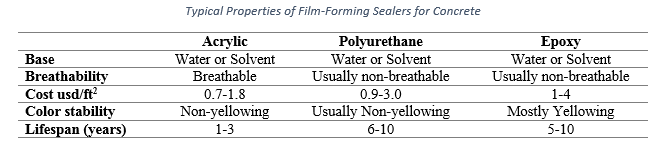

Film-forming sealers for concrete can be made of acrylic, polyurethane, or epoxy.

Acrylic topical sealers

Acrylic sealers can be either water based or solvent based. In general, they are cost effective, easy to apply, breathable, and non-yellowing. In fact, acrylic sealers are very common in many applications due to their numerous benefits.

However, acrylic sealers provide a thin protective layer, which generally lasts for only a couple of years. In addition, acrylic tends to wear fast in high traffic areas and those exposed to hot tire pick up.

Usually, these topical types of concrete sealers are suitable for interior and exterior applications. These include decorative concrete, stamped concrete, pavers, and exposed aggregate concrete.

Polyurethane topical sealers

Polyurethane sealers can also be either water based or solvent based. In general, they have numerous benefits including high wear resistance, good chemical resistance, and high durability. In addition, due to their UV stability, polyurethanes are non-yellowing, which means that they do not turn yellow with time under direct sunlight exposure. Furthermore, polyurethanes are almost as twice as thick as acrylics. Hence, they provide a longer-lasting protection with less maintenance.

However, these topical types of concrete sealers, like any other material, also has its disadvantages. Generally, most polyurethanes are non-breathable, which means that they do not allow moisture to escape. This can be a major disadvantage for some exterior applications. Also, polyurethanes are sensitive to moisture when fresh, and should only be applied to dry surfaces. In addition, they are relatively more expensive than acrylic.

Most polyurethane sealers are suitable for both interior and exterior applications. Usually, their applications include countertops, exposed aggregate concrete, stamped concrete, colored concrete, and floors with high traffic. Also, they are suitable for patios, driveways, and walkways, however, it is important to account for breathability.

Epoxy topical sealers

Epoxy sealers can also be either water based or solvent based. In general, they are thicker than polyurethanes, and provide good strength, abrasion resistance, and high durability. In addition, epoxy sealers tend to have a fairly long lifespan. Furthermore, one of the most important benefits of epoxies is their strong bond to concrete.

However, this type of sealers is somehow rigid compared to polyurethane or acrylic. In addition, most epoxy sealers are not UV stable, and tend to turn yellow under direct sunlight exposure. Hence, they are limited to interior applications. Furthermore, epoxies are usually non-breathable, and can entrap moisture. Also, similar to polyurethanes, these topical types of sealers are moisture sensitive when fresh and should only be applied to dry surfaces.

Usually, epoxy sealers are suitable for high traffic floors such as garages and industrial warehouses, in addition to commercial kitchen applications such as floors and countertops.

Penetrating concrete sealers

Penetrating sealers are chemicals that penetrate into the concrete and provide a good overall protection against stains, chemicals, deicers, and freeze and thaw cycles. These types of sealers usually have a little or no effect on the appearance of the substrate, unlike topical sealers.

In fact, penetrating sealers can be mainly classified, according to their working mechanism, into three types: water repellents, water and oil repellents, and densifiers and hardeners.

Water repellent sealers for concrete

This type of penetrating sealers includes Silanes, Siliconates, and Siloxanes. In general, similar to all penetrating concrete sealers, water repellents have a little or no effect on the appearance of concrete.

During the application of these sealers, they penetrate and form a cross-linked silicone resin to fill the pores in concrete. In fact, the depth of penetration of these types of sealers is very important, and is related to various factors such as their composition and the porosity of concrete.

Silanes

Silanes can usually infiltrate deep into the concrete surface, since their reaction is relatively slow and they have a small molecular structure. In general, this type of sealers has numerous benefits in repelling water and protecting concrete against salts, deicers, dirt, stains, efflorescence, mold, fungus, and freeze and thaw cycles. In fact, silanes can penetrate deep enough to provide a good corrosion resistance to steel reinforcements.

However, due to their small molecular structure, the application of silane sealers on a relatively porous substrate will lead to a low coverage. In fact, it often requires multiple coats on porous substrates, which not only increases the cost, but can also affect the appearance of concrete. In addition, the cost of this type of sealers is often higher than those of the other types.

Hence, silane sealers are usually suitable for dense concrete having a low porosity. For example, silanes are applicable for high strength concrete, ultra-high strength concrete, facades, and general precast concrete elements.

Siliconates

Siliconate concrete sealers have a medium sized molecular structure, which is relatively bigger than that of silanes. Hence, they often have higher coverage rates than silanes on similar substrates. In addition, siliconate concrete sealers are eco-friendly since they are mostly water based not solvent based, with little or no volatile organic compounds (VOCs). Furthermore, some siliconate products can be used prior to the application of topical sealers. This helps not only to increase the adhesion of the latter sealer, but also to provide additional protection to concrete.

Also, a unique advantage of this type of sealers is that it can be used in curing and sealing products.

Thus, siliconate concrete sealers are suitable for concrete with low porosity and also for concrete with high porosity. Its common uses include indoor applications such as garage floors and industrial warehouses, and outdoor applications such as pool decks, patios, and driveways.

Siloxanes

Siloxanes have a relatively large sized molecular structure and are the least reactive. Thereby, they usually have much higher coverage rates than silanes or siliconates on a similar surface.

In addition, similar to silanes, siloxanes can be either water based or solvent based. The water based siloxanes are usually eco-friendly and have a little to no VOCs. But, they do not usually perform as good as solvent based ones, since they do not penetrate as deep.

However, siloxanes have major disadvantages, especially with improper application. In general, they tend to wear much faster than other penetrating sealers and do not last as long. This is mainly because of their large sized molecular structure, thus not penetrating deep into the concrete surface.

Hence, this type of sealers is generally only suitable for very porous concrete surfaces. Usually, its applications include very porous concrete floors, blocks, and porous vertical concrete elements.

In addition, sometimes Siloxanes are modified with Silanes in order to form a product which has a good penetration depth and an acceptable coverage rate and price.

Water and oil repellent concrete sealers

This penetrating type of concrete sealers mainly includes fluorinated materials. In fact, fluorinated materials are a relatively newer technology in the concrete sealers industry. In general, they often have a small sized molecular structure and can easily penetrate into the surface of concrete. Their main advantage is that they owe both water repelling and oil repelling properties. In addition, they often require only one coat on suitable substrates. However, this type of concrete sealers is relatively more expensive than other sealers.

Densifying and hardening sealers for concrete

This type of penetrating sealers mainly includes Silicates (sodium silicate, potassium silicate, and lithium silicate) which are generally water based and are applied in several coats. In fact, when they penetrate into the concrete, silicates react with lime, a product of the hydration mechanisms of cement, to produce more complicated crystalline compounds. These crystalline compounds fill the pores in concrete, thus densifying it and increasing its strength and hardness.

However, these types of concrete sealers are not water repellents. As we explained, they chemically react and fill pores and voids in concrete, thereby reducing its permeability.

Conclusion

Concrete sealers can be classified into two broad types, topical and penetrating sealers. And these types of sealers may have a different overall performance. However, it is important to know the different types and their further classification, to understand their pros and cons, and to know their suitable application.

Bibliography

- Girard, J. (2005). Sealer Options for Concrete Countertops. The Concrete Countertop Institute.

- Guy, T. C. (2016). Overview of Different Types of Penetrating Concrete Sealers. Retrieved from Concrete Sealers USA.

- Safiuddin, M., & Soudki, K. A. (2011). Sealer and coating systems for the protection of concrete bridge structures. International Journal of the Physical Sciences, 6(37), 8188-8199.