Concrete Mix Design Calculator (Based on the ACI Code)

Concrete mix designing is the process of selecting the right amount of constituent materials to produce a mixture with the desired properties. Practically, designing the optimum mixture that achieves the desired mechanical, physical, and durability properties at the lowest cost is not an easy process. The process starts by designing and finding the proper quantities for trials mixtures according to international codes and standards.

With our concrete mix design calculator, you can easily find the quantities of each ingredient of your mixes based on the ACI code with only a few clicks.

Note:

Use the first page to fill out the input data in metric or imperial units, and check out the results, notes, and calculation parameters on the next pages.

This tool provides a simple and a fast way to design your concrete mixtures, based on the ACI code.

The concrete mix design calculator consists of three pages, the data input page, results page, and calculations page. Thus, it is simple, all you have to do is fill the input data on the first page and check all the data you need on the following pages. In fact, this concrete mix design calculator performs all the checks and calculations, and provides you with all the output results you need. In addition, we further simplified the input fields with the help icons, to give you the simplest experience.

As we previously mentioned, the first page is the data input page. In fact, this page can be divided into three main sections, the general data input, exposure conditions, and properties of constituent materials.

Step 1: General data input

Compressive strength up to 45 MPa (metric) and up to 6000 PSI (imperial)

Use this field to enter the specified compressive strength in mega-pascal or pounds per square inch. The value must be within the limits of 15 to 45 MPa, or 2,000 to 6,000 PSI.

Standard deviation

New trial mixtures usually do not have enough data to calculate the standard deviation, and thereby the user should choose the “no Data Available” option in this case. However, for concrete mixtures with a known standard deviation, the user can select the second option and proceed in providing the value and number of tests.

Slump

Then, the user can simply select the slump requirements in the next drop-down menu. This menu provides three ranges including 25 to 50, 75 to 100, and 150 to 175 millimeters for metric. And, 1 to 2, 3 to 4, and 6 to 7 inches for imperial.

Special conditions

Afterwards, the user selects the special conditions, if available, which may affect the calculation process. In this drop-down menu, you can choose if the placement method is by pumping, thereby requiring a higher workability. Or, if the concrete mix design is for applications such as concrete pavements, requiring a lower workability.

Air entrained concrete

Finally, in this section, the user can specify whether the concrete is air entrained or not.

Step 2: Exposure conditions

This section includes four major durability concerns or exposures for concrete trial mixtures. These include sulfate exposure, freeze and thaw cycles, water contact, and chloride exposure.

Sulfate exposure

First, in the sulfate exposure class drop-down menu, the user can choose one of the four exposure classes to sulfates. Also, depending on the exposure class, the user may need to provide the type of cement.

Freeze and thaw exposure

Second, the user can select from the drop-down menu one of the three freeze and thaw exposure classes. Also, depending on the class, the user may need to provide the type of concrete, whether it is plain or reinforced.

Water contact exposure

Third, the user should select the water exposure class, whether being W0, W1, or W2.

Chloride exposure

And finally, in this section, the user selects the chloride exposure class. Also, depending on the class, the user may need to specify whether the concrete is pre-stressed or not.

Step 3: Properties of constituent materials

Cement and supplementary cementitious materials

The user should specify the specific gravity of cement, and also that of the supplementary cementitious material in addition to its replacement percentage. In brief, this concrete mix design calculator allows you to select one of three types of supplementary cementitious materials.

Aggregates

Afterwards, the user should determine the the nominal maximum aggregate size, particle shape condition, and dry-rodded bulk density of the coarse aggregates. Then, the user selects the fineness modulus of the fine aggregates. And of course, the user also needs to provide basic data such as the specific gravity, moisture content, and water absorption of both aggregates.

Admixtures

Finally, in this section, the user fills the data input in case using water-reducing admixtures and/or air-entraining agents. In addition to the specific gravity and dosage of admixtures, the user should specify the water reduction capacity of the water reducer at the specific dosage.

Step 4: Results

The next step is to check your results on the second page. In fact, this concrete mix design calculator shows you two results for the trial mixes. The first considers that the aggregates are in SSD condition, and do not contribute to the free water. Whereas, the second takes into account the moisture content and absorption of aggregates and their effect on the water content.

Furthermore, this concrete mix design calculator provides the user with technical checks and notes on the same page. For instance, you can easily check if the strength of concrete is sufficient for the durability exposure conditions. Or, you can check the approximate air content requirements or the water to cementitious materials ratio. In addition, the 12 notes provide you with plenty of important technical information.

Step 5: Calculation parameters of the mix design

Moreover, this concrete mix design calculator provides you with various calculation parameters, on the third page, to better apprehend your results. This page includes the important steps, equations, calculations, and plenty of other essential data.

Step 6: Check your results

We always recommend that the users check their results. The notes are a vital source of information, in addition to the calculation parameters. Hence, if you find any illogical results, first check these two sections. We also highly encourage any user to contact us for any question, note, suggestion, or if they think that the calculator is causing any miscalculation.

Design a trial mix having a specified compressive strength of 35 MPa. This mix should have a slump of 75 mm, which will be pumped to place. It will be exposed to the following classes based on ACI 318-19: S0, F2, W1, and C0.

The cement is of ASTM C150 Type I, with a specific gravity of 3.16.

In addition, silica fume with a specific gravity of 2.21 will be used at a dosage of 8% by weight of the total cementitious materials.

The coarse aggregate is of a round shape, having a nominal maximum particle size of 19 mm, bulk density of 1580 kg/m3, specific gravity of 2.78, moisture content of 0.6%, and absorption of 1.5%.

The fine aggregate has a fineness modulus of 2.6, specific gravity of 2.72, moisture content of 6.4%, and absorption of 3.2%.

A water reducing admixture will be used at a dosage of 1.4% by weight of the cementitious materials, with an approximate water reduction capacity of 22% at this dosage, having a specific gravity of 1.1.

Also, due to the exposure conditions, an air-entraining agent will be used at a dosage of 0.6% by weight of the cementitious materials, having a specific gravity of 1.0.Solution

Data input

In this concrete trial mix calculator, the first page consists of three sections, the general data input, exposure conditions, and properties of constituent materials.

1. General data input

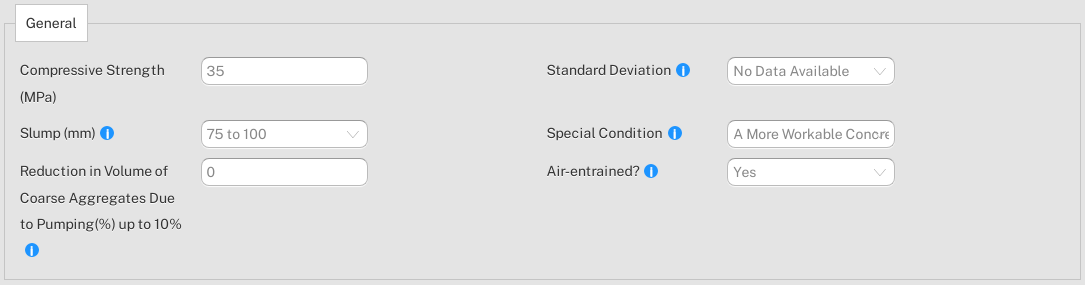

Based on the given data, the input for the compressive strength, standard deviation, slump, placement method, and air-entrainment conditions is as follows:

- Specified compressive strength = 35 MPa.

- Standard deviation = No data available.

- Slump (mm)= 75 to 100.

- Special condition = Placement method by pumping. Hence, a new input field unlocks, which requires specifying the reduction in the volume of coarse aggregates up to 10%. However, in this example we will have the first trial mix without any reduction in the coarse aggregate.

- Reduction in Volume of Coarse Aggregates Due to Pumping(%) up to 10% = 0.

- Air entrained = Yes.

2. Exposure conditions

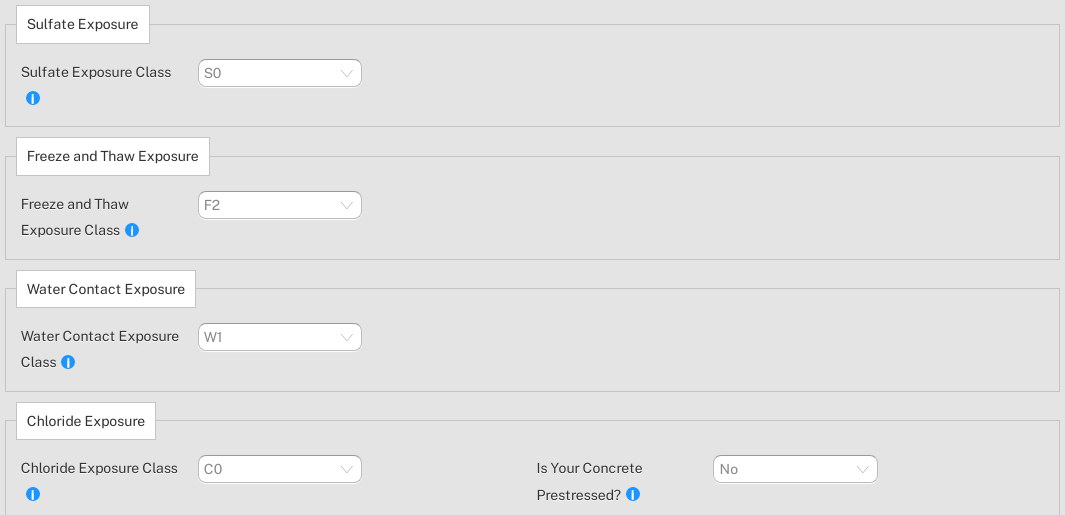

Also, based on the given data for the exposure conditions, the input in the second section of the concrete calculator for the sulfate, freeze and thaw, water contact, and chloride exposure conditions are as follows:

- Sulfate exposure class = S0.

- Freeze and Thaw Exposure Class = F2.

- Water Contact Exposure Class = W1.

- Chloride Exposure Class = C0.

- Is Your Concrete Prestressed = No.

3. Material properties

Then, in the third section, we will specify the properties of materials based on the given data. For the binding materials, the input is as follows:

- Specific Gravity of Cement = 3.16.

- Type of mineral admixture = Silica fume.

- Specific Gravity of fly ash= 2.21.

- Replacement Percentage of the Cementitious Materials = 8.

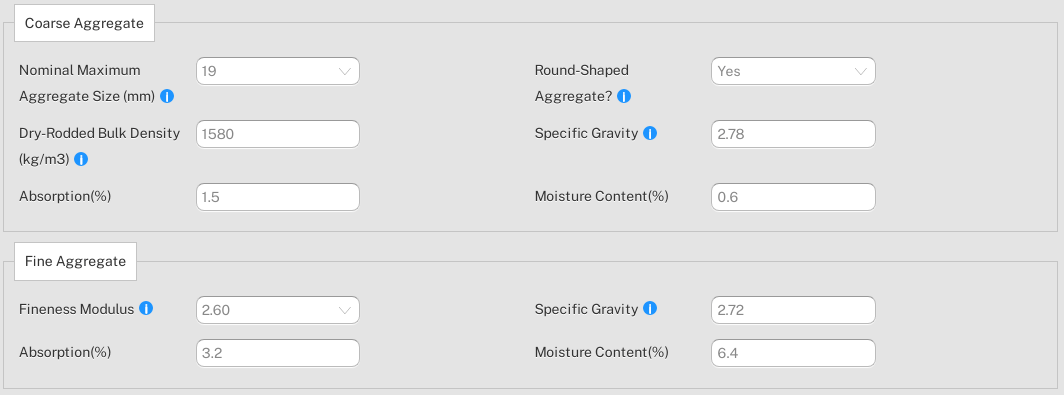

Then for the coarse and fine aggregates, we will enter the following parameters:

- Nominal Maximum Aggregate Size (mm) = 19.

- Round-Shaped Aggregate = Yes.

- Dry-Rodded Bulk Density (kg/m3) = 1580.

- Specific Gravity of coarse aggregates = 2.78.

- Absorption(%) of coarse aggregates = 1.5.

- Moisture Content(%) of coarse aggregates = 0.6.

- Fineness Modulus of fine aggregates = 2.6.

- Specific Gravity of fine aggregates = 2.72.

- Absorption(%) of fine aggregates = 6.4.

- Moisture Content(%) of fine aggregates = 3.2.

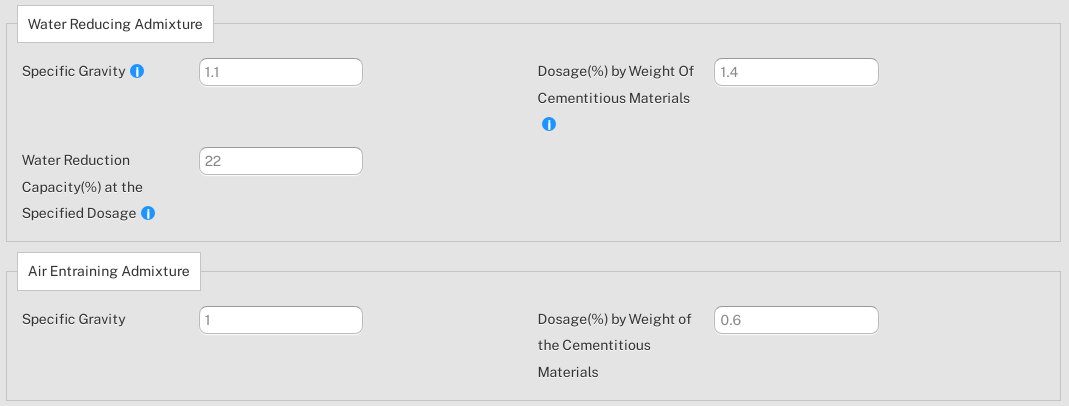

Afterwards, we will input the main data for the water reducer and the air entraining agent as follows:

- Specific Gravity of the water reducing admixture = 1.1.

- Dosage(%) by Weight Of Cementitious Materials of the water reducing admixture = 1.4.

- Water Reduction Capacity(%) at the Specified Dosage = 22.

- Specific Gravity of the air entraining admixture = 1.0.

- Dosage(%) by Weight of the Cementitious Materials of the air entraining admixture = 0.6.

Results

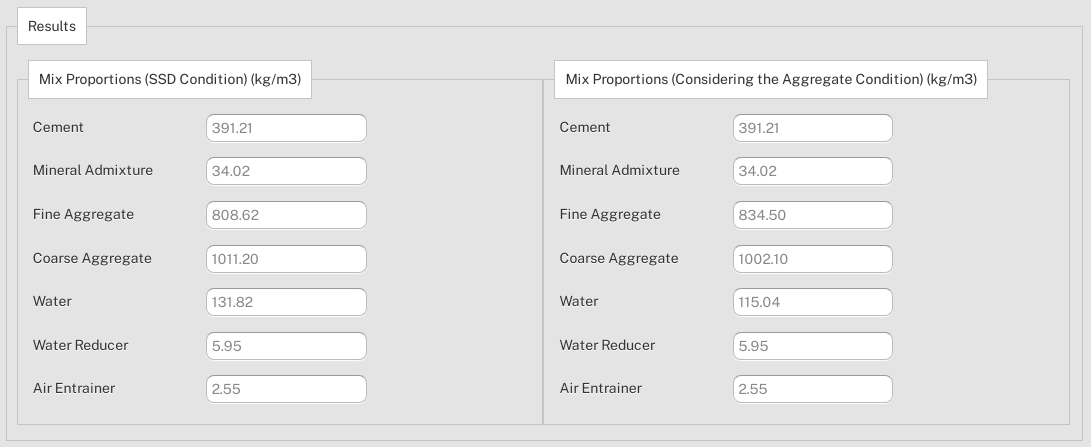

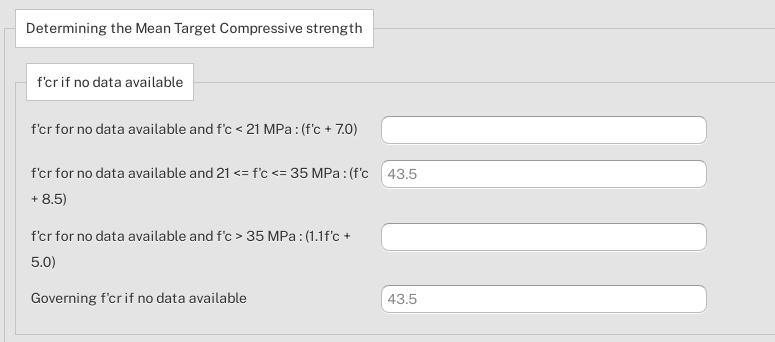

After we are done with all the input, we will check the results on the next page. In fact, this calculator presents the mix proportions for the trial mix in two conditions, one as SSD condition of aggregate, and the other considering their actual moisture and absorption conditions.

Checks

Afterwards, right below the mix proportions, we this tool provides essential checks for various parameters. These include the compressive strength requirements, air entrainment, governing air content, and the governing w/c.

As the following image shows, the compressive strength meets the requirements of the exposure conditions in this example. Also, the fifth check informs us that air-entrained concrete is adequate since the F2 exposure requires so. In addition, it shows that the required air content is 6%, and that the governing w/c is 0.31.

Notes

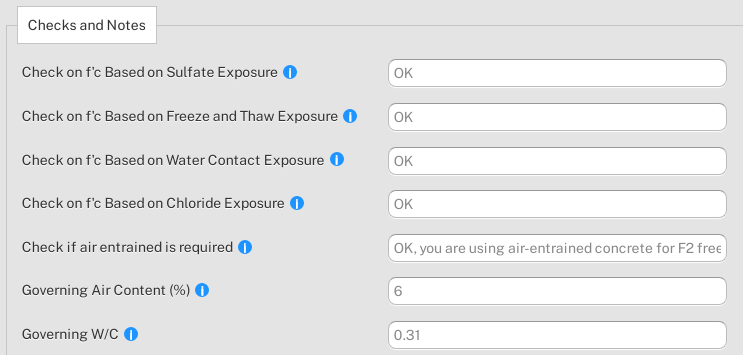

Moreover, after the checks, this concrete trial mix calculator provides twelve valuable notes.

Note 1

The first note shows that there is no restrictions on the type of cement in this example.

Note 2

The second note informs us that there are no restrictions on using calcium chloride admixtures.

Note 3

The third note shows us that in this example, it is permitted to reduce the air-content by 1%.

Note 4

The fourth note is related to the maximum allowable content of supplementary cementitious materials in F3 exposure class. However, in this example, the concrete is not exposed to F3, and hence the field is left empty.

Note 5

The fifth note informs us that in this example we assigned a water exposure class of W1. Thus the aggregates must not be alkali reactive, tested according to ASTM C1778. Also, that we should refer to section 26.4.2.2(d) and to the commentary section on Exposure Class W1 in ACI 318-19 R19.3.2

Note 6

The sixth note informs us about the maximum water soluble ion by mass of cementitious materials, which is 1% in this example.

Note 7

The seventh note is related to the required cover to reinforcements for C2 exposure class. However, we assigned a C0 exposure class, and thus this note is left empty.

Note 8

The eighth note simply informs the user about the reduction in the aggregate volume due to the special conditions. In this example, it shows that there is no reduction in the aggregate volume as per our input.

Note 9

The ninth note is about the governing cementitious content. In this example, it is the value calculated based on the water to cement ratio and water content.

Note 10

The tenth note informs the user about the governing w/c. Here, it shows that the value calculated based on the water to cement ratio and water content is governing.

Note 11

The eleventh note is related to the use of maximum aggregate size of 150 mm with a slump of 150 to 175 mm. Hence, this note is left empty based on our input.

Note 12

The twelfth note informs us in case the target compressive strength exceeds the maximum value according to the code. Here, the field is empty which indicates that the target compressive strength is within the covered range.

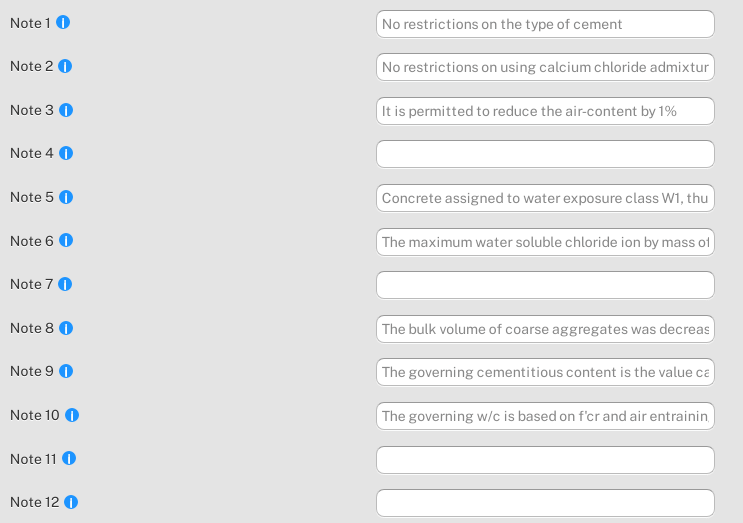

Calculation parameters

The third page mainly presents numerous calculation parameters. These include the governing target compressive strength, w/c, air, water content, cementitious materials content, the volumes of coarse and fine aggregate, and the water contribution by each aggregate.

The governing target compressive strength

The target compressive strength in this example is 43.5. Basically, this value is obtained by adding 8.5 MPa to the specified strength which is 35 MPa.

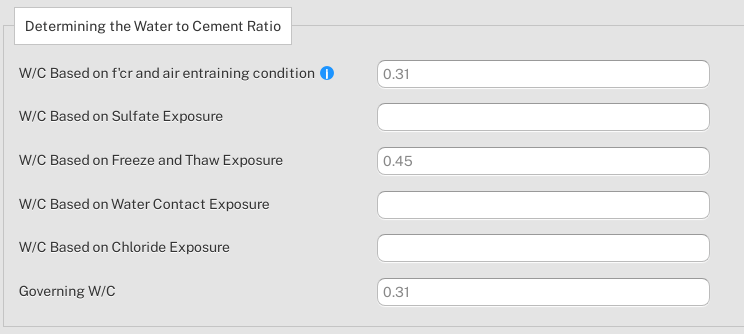

The governing water to cementitious materials ratio

The governing w/c is the smallest ratio between the w/c requirements for the exposure conditions and the w/c based on ACI 211.91. In the following example, the w/c of the former is 0.45, whereas that of the latter is 0.31. Hence the latter is the governing ratio.

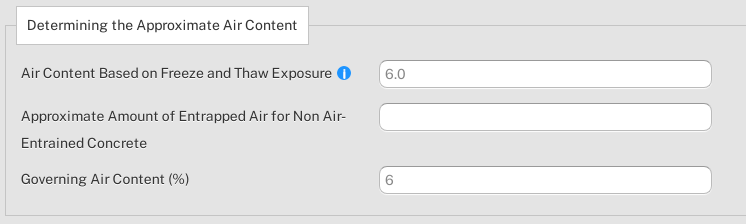

The approximate and required air content

Also, this concrete trial mix calculator presents the air content requirements or approximate entrapped air. In this example, the air content should be 6%, with a tolerance of +/- 1.5%.

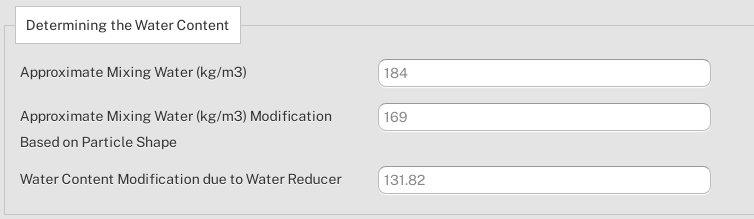

The water content

This calculator determines the approximate mixing water content in accordance with ACI 211.1-91 Table 6.3.3. In addition, it performs any necessary modifications depending on the aggregate shape. Furthermore, it also performs the final modification in case of the incorporation of a water reducer.

Here, the approximate mixing water is initially 184 kg/m3. However, due to the use of aggregate of a round shape, the value is reduced to 169 kg/m3. In addition, we are using a water reducer with a reduction capacity of 22%, which further reduces this content to 131.82 liters per cubic meter of concrete.

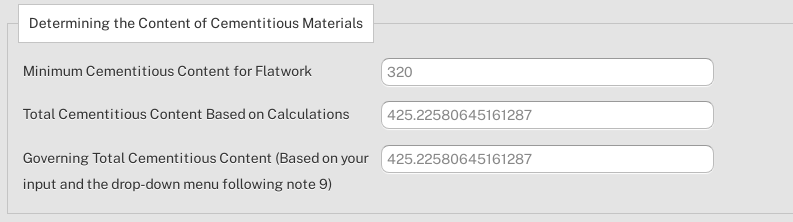

The cementitious materials content

The governing content of cementitious materials is the higher value between the minimum requirements for flatwork and the calculated value. In fact, the latter relies on the water content and the water to cementitious materials ratio. In this example, the former is 320 kg/m3, whereas the latter is 425.23 kg/m3. Hence, the latter governs. However, this value represents the content of cement and silica fume, with a weight percentage of 92% and 8%, respectively.

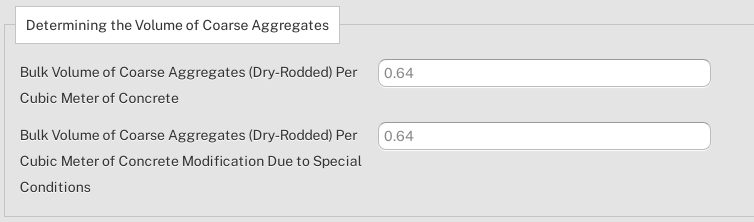

The volume of coarse aggregates

Also, this concrete trial mix calculator presents the volume of coarse aggregates, in addition to its modifications due to the placement method. In this example, the volume of coarse aggregates is 0.64, with no modification based on our input.

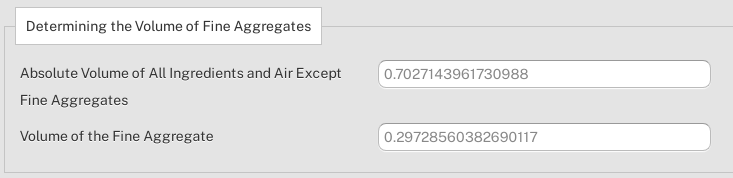

The volume of fine aggregates

The, in accordance with the code, this calculator uses the absolute volume method to calculate the volume of fine aggregates. Briefly, the total volume of all ingredients and air except fine aggregate is 0.702 m3. Hence, the volume of fine aggregate is equal to the unit volume (1 m3) minus 0.702, which yields about 0.297 m3.

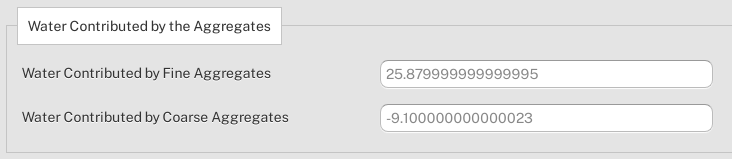

The water contributed by the aggregates

Finally, this tool shows the water contribution of both aggregates, which mainly relies on the input of moisture and absorption of each. In this example, the fine aggregates contributed to 25.88 liters of water, whereas the coarse aggregates contributed to negative 9.1 liters (since the absorption is higher than the moisture content).

Example

Let us consider the following concrete mix design example:

A concrete with a specified compressive strength of 3750 PSI is required for a slab on ground. The slump should be between 3 and 4 inches, and the placement method is by pumping. The exposure conditions following the ACI 318-19 are briefly a follows: S1, F1, W0, and C1.

In addition, the cement is of ASTM C150 Type II, and has a specific gravity of 3.10.

Also, fly ash with a specific gravity of 2.18 will be used as a partial replacement of cement at 12% by weight of the total cementitious materials.

The coarse aggregate is of a round shape and has a maximum particle size of 3/4 inches, bulk density of 104 lb/ft3, and specific gravity of 2.72.

The fine aggregate has a fineness modulus of 2.6 and a specific gravity of 2.68.

A water reducing admixture will be added at a dosage of 1.2% by weight of the cementitious materials, with an approximate water reduction capacity of 18% at this dosage.

Also an air-entraining admixture will be added at a dosage of 0.5% by weight of the cementitious materials.

The specific gravity of the water reducer and air-entrainer are 1.09 and 1.02 respectively.

The absorption and moisture content of the coarse aggregate are 3% and 1.2% respectively. Whereas, for fine aggregate the absorption and moisture content are 4 and 7.5% respectively.Solution

Data input

The data input page in this concrete mix design calculator consists of three main sections, the general data input, exposure conditions, and properties of constituent materials.

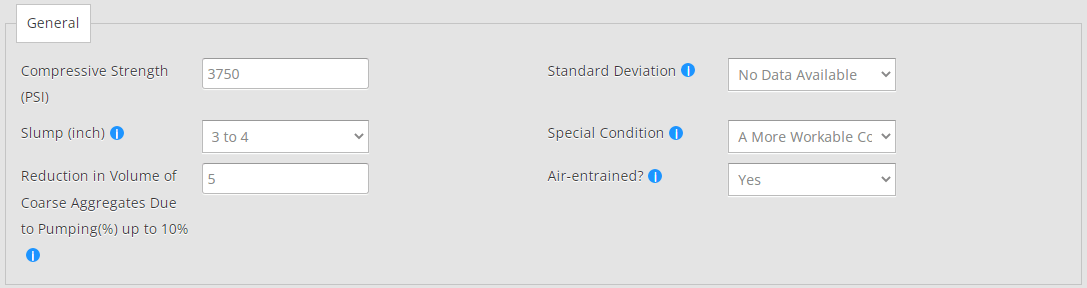

1. General data input

The general data input includes the compressive strength, standard deviation, slump, placement method, and air-entrainment conditions. Based on the given data, we will input the following:

- Specified compressive strength = 3750 PSI.

- Standard deviation = No data available.

- Slump = 3 to 4 inches.

- Special condition = Placement method by pumping. Here, a new input category opened for this placement method, which requires specifying the reduction in the volume of coarse aggregates up to 10%. We will consider a reduction of 5% in this example.

- Reduction in Volume of Coarse Aggregates Due to Pumping(%) up to 10% = 5%.

- Air entrained = Yes. We will choose air entrained concrete since the freeze and thaw exposure conditions require air-entrained concrete.

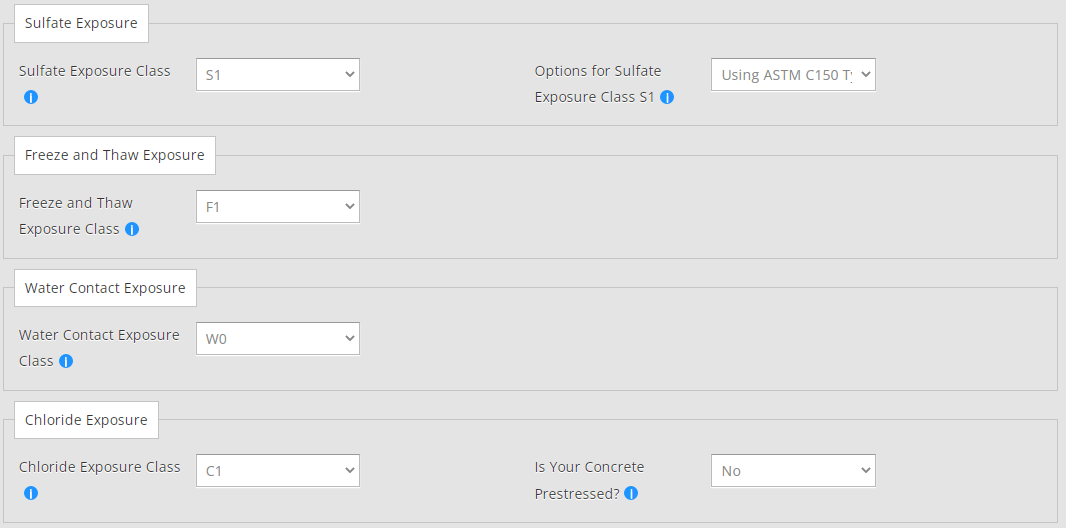

2. Exposure conditions

The exposure conditions in this mix design calculator include sulfate, freeze and thaw, water contact, and chloride exposure conditions. In this example, the exposure conditions are briefly given for simplicity following the ACI 318-19. Thereby, we simply input the following data:

- Sulfate exposure class = S1. This opens a second category for choosing the type of cement.

- Options for Sulfate Exposure Class S1 : we will choose the first option, since the type of cement used in this example is Type II.

- Freeze and Thaw Exposure Class = F1.

- Water Contact Exposure Class = W0.

- Chloride Exposure Class = C1.

- Is Your Concrete Prestressed = No.

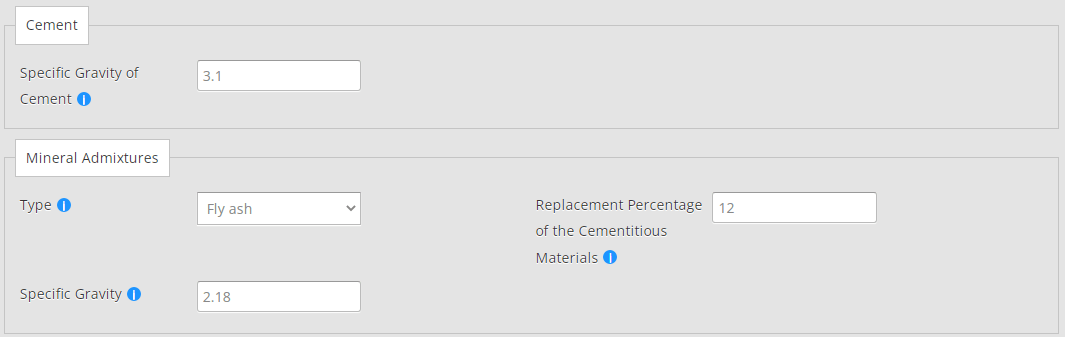

3. Material properties

Also, all the required material properties are simply given in this example, hence we will input the following:

- Specific Gravity of Cement = 3.1.

- Type of mineral admixture = Fly ash.

- Specific Gravity of fly ash= 2.18.

- Replacement Percentage of the Cementitious Materials = 12.

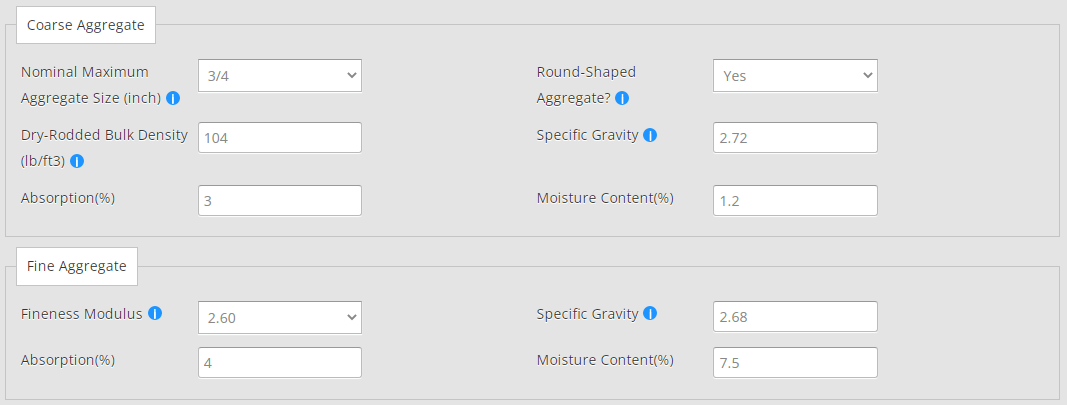

- Nominal Maximum Aggregate Size (inch) = 3/4.

- Round-Shaped Aggregate = Yes.

- Dry-Rodded Bulk Density (lb/ft3) = 104.

- Specific Gravity of coarse aggregates = 2.72.

- Absorption(%) of coarse aggregates = 3.

- Moisture Content(%) of coarse aggregates = 1.2.

- Fineness Modulus of fine aggregates = 2.6.

- Specific Gravity of fine aggregates = 2.68.

- Absorption(%) of fine aggregates = 4.

- Moisture Content(%) of fine aggregates = 7.5.

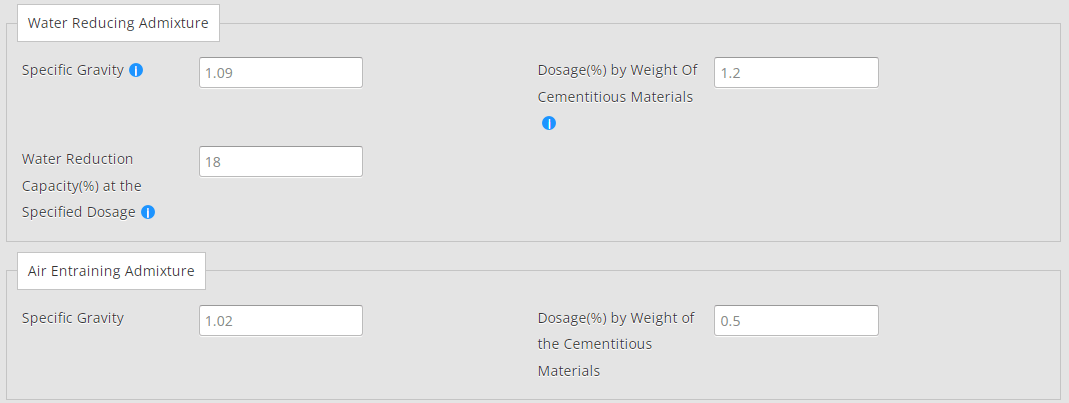

- Specific Gravity of the water reducing admixture = 1.09.

- Dosage(%) by Weight Of Cementitious Materials of the water reducing admixture = 1.2.

- Water Reduction Capacity(%) at the Specified Dosage = 18.

- Specific Gravity of the air entraining admixture = 1.02.

- Dosage(%) by Weight of the Cementitious Materials of the air entraining admixture = 0.5.

Results

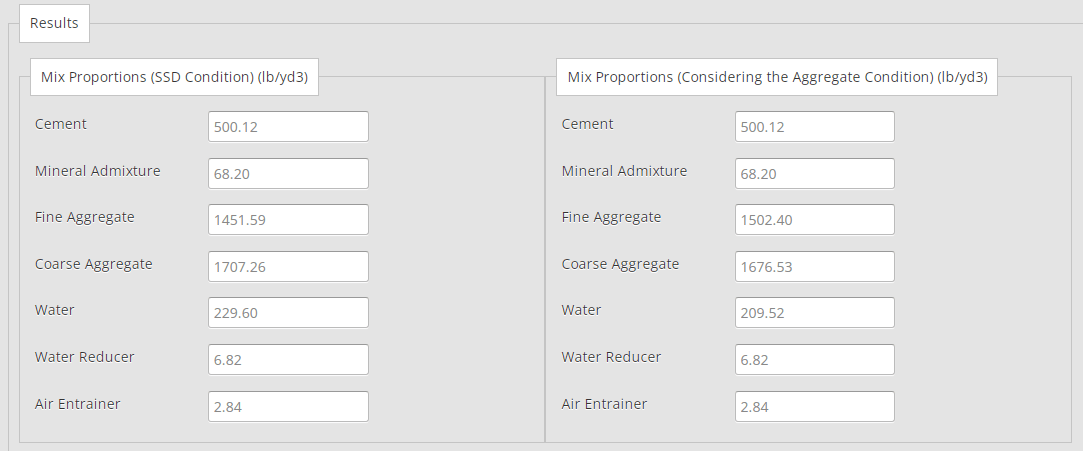

After we input the data in the first page, we will check the next page for the results. The following image summarizes the concrete mix proportions for this example.

The above image shows the mix proportions in pounds per cubic yard for SSD condition of aggregates on the left and considering the condition of aggregates on the right. The difference between both is only in the contents of fine aggregate, coarse aggregate, and water.

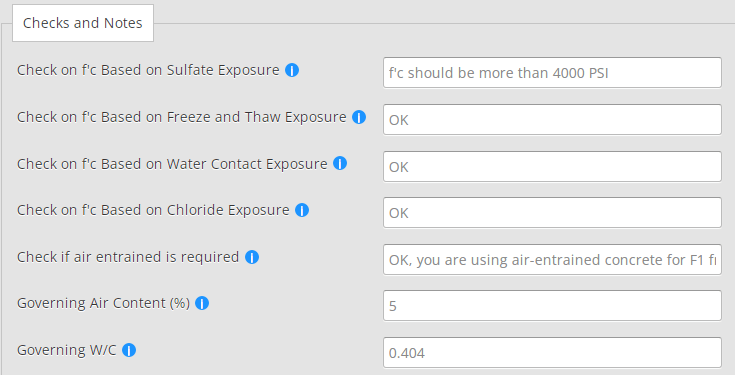

Checks

On the same page, just under the results of the concrete mix proportions, the tool provides a list of seven essential checks. The calculator checks if the compressive strength meets the minimum requirements based on the exposure conditions. Also, it checks if air entrainment is necessary based on the freeze and thaw exposure. In addition, it also provides the governing air content, and the governing water to cementitious materials ratio.

In this example, the specified compressive strength does not meet the minimum requirements for the sulfate exposure conditions. Hence, in order to meet the S1 exposure class requirements, we should increase the compressive strength from 3750 PSI to a minimum of 4000 PSI. Also, the air entrainment check shows that we specified air-entrained concrete which is necessary based on the F1 exposure conditions. Furthermore, it shows that the governing air content should be 5%. In addition, it shows that the governing water to cementitious materials ratio is 0.404.

Notes

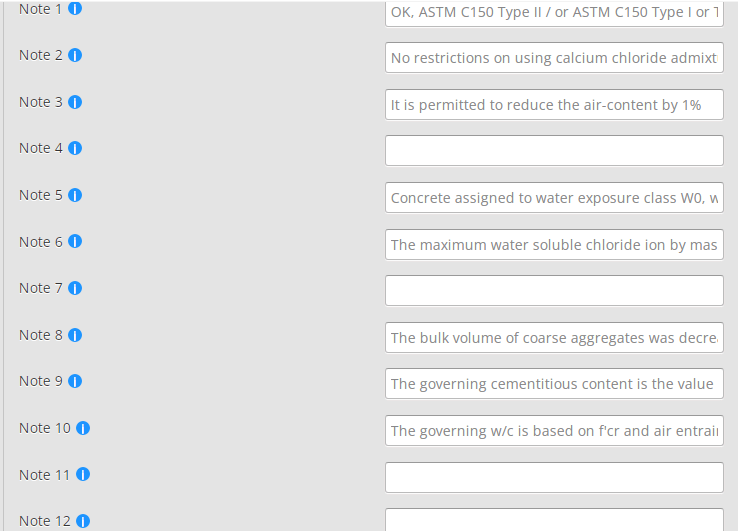

Furthermore, just below the checks, this concrete mix design calculator provides twelve important notes.

Note 1

The first note is to inform the user in case there is any restriction on the type of cement based on the sulfate exposure. In this example, this note shows that the type of cement used meets the sulfate requirements.

Note 2

The second indicates if calcium chloride is prohibited in the mix design based on the sulfate exposure. It shows no restrictions since the sulfate exposure class in the example is S1, whereas the prohibition is for classes S2 and S3.

Note 3

The third note shows whether you are permitted to reduce the air content by 1% based on ACI 318-19. In this example, we are permitted to reduce the air content by 1%.

Note 4

The fourth note informs the user about the maximum allowable content of mineral admixtures in F3 freeze and thaw conditions. Thereby, the below image shows this note as empty since the concrete in this example is not exposed to F3 conditions.

Note 5

The fifth note is about the water contact exposure conditions. It shows if the water contact sets any limits or requirements. In this example, it shows that there are no special requirements since the exposure class is W0.

Note 6

The sixth note is about the maximum water soluble ion by mass of cementitious materials. In our example, it shows a value of 0.3%.

Note 7

The seventh note is to inform the user about the cover to reinforcements requirements for C2 exposure class. Hence, this field is empty in this example since the chloride exposure class is C1.

Note 8

The eighth note is about the modification in the volume of coarse aggregate due to the placement conditions. In this example, the note shows that bulk volume of coarse aggregates was decreased by 5% due to concrete pumping.

Note 9

The ninth note is to inform the user about the governing cementitious content. Here, the governing cementitious content is the value calculated based on the water to cement ratio and water content.

Note 10

The tenth note indicates the governing water to cementitious material. In this example, the governing w/c is based on the compressive strength and air entraining condition.

Note 11

The eleventh note is related to the use of maximum aggregate size of 6 inches with a slump of 6 to 7 inches. In our example, the maximum aggregate size is 3/4 inches and the slump is 3 to 4 inches, hence this field is empty.

Note 12

The twelfth note simply informs the user in case the target compressive strength exceeds the maximum value according to the code. Here, the field is empty which indicates that the target compressive strength is within the covered range.

Calculation parameters

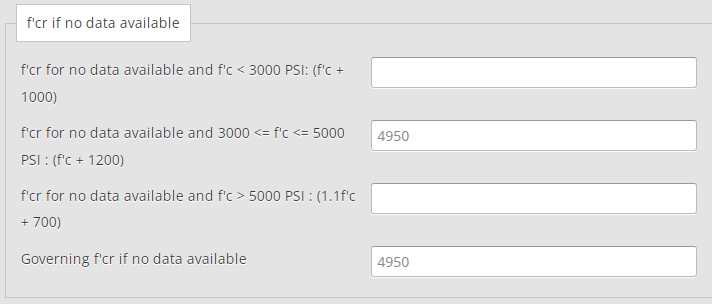

The governing target compressive strength

The third page in this concrete mix design calculator shows various calculation parameters. In this example, the following image shows the governing target compressive strength. Briefly, the specified compressive strength was 3750 PSI, with no data of the standard deviation. Hence, this value lies in the range between 3000 and 5000 PSI. Consequently, based on the equations followed the targeted compressive strength is calculated to be 4950 PSI.

The governing water to cementitious materials ratio

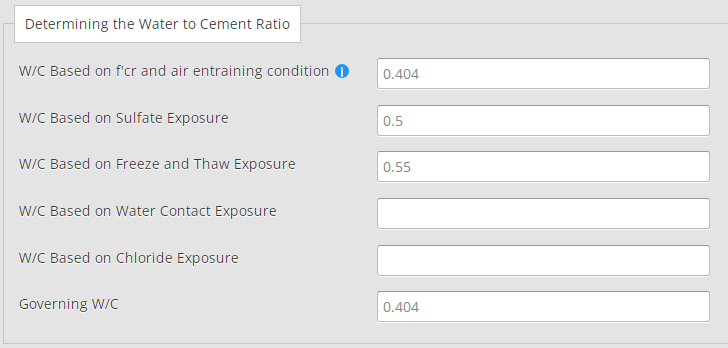

The governing water to cementitious materials ratio is the least value between the w/c requirements for the exposure conditions and the w/c based on ACI 211.91 Table 6.3.4(a). In this example, the w/c based on the latter is 0.404. Whereas, the w/c based on the sulfate and freeze and thaw exposure conditions is 0.5 and 0.55 respectively. Thus the governing value is 0.404 as shown in the following image.

The approximate and required air content

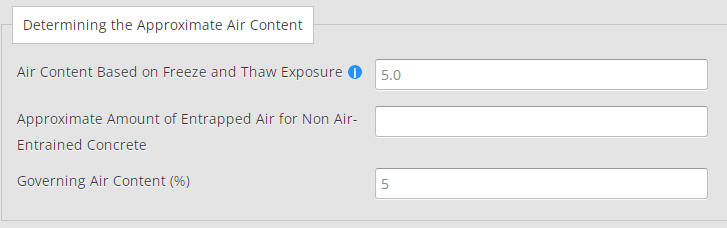

In this section of the concrete mix design calculator, the air content requirement for air entrained concrete is determined with a tolerance of +/- 1.5%. Also, the approximate entrapped air content is determined for non-entrained concrete. In this example, the following image shows that the air content should be 5% with a tolerance of +/- 1.5%.

The water content

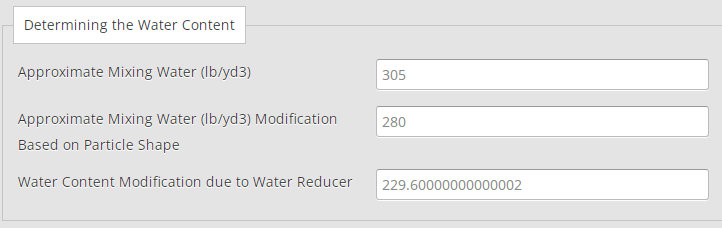

In this calculator, the approximate amount of mixing water is based on the ACI 211.1-91 Table 6.3.3. Also, it takes into consideration the necessary modifications in case of round aggregates, and the incorporation of a water reducing admixture. In our example, the initial approximate mixing water content is 305 pounds per cubic yard. Then, this value is reduced to 280 pounds per cubic yards due to the round shaped coarse aggregate. And finally, it is further modified due to the use of a water reducing admixture, which further reduces the value by 18%, based on the input.

The cementitious materials content

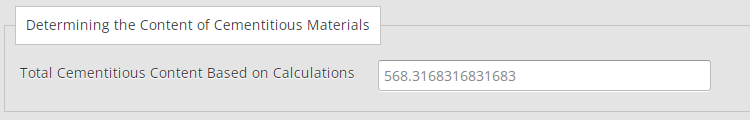

The minimum requirements for the cementitious materials’ content is based on the water to cementitious materials ratio and water content. For instance, in this example the w/c is 0.404, and the water content is 229.6. Thereby, the cementitious content equals 229.6/0.404, which yields 568.3 pounds per cubic yard. It is important to note that this value represents the amount of cement and fly ash in this example, with 88% cement and 12% fly ash.

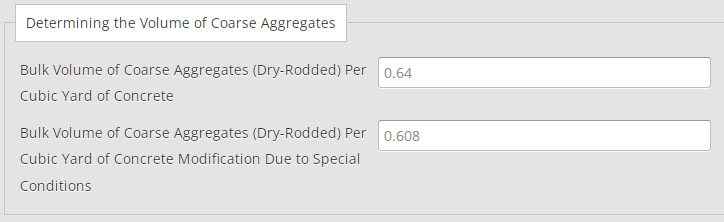

The volume of coarse aggregates

This part of the concrete mix design calculator informs the user about the bulk volume of the coarse aggregate per cubic yard of concrete. In addition, it shows the modification due to the placement conditions. Here, the initial volume is 0.64 cubic yards, which is then reduced by 5% due to placement by pumping to become 0.608.

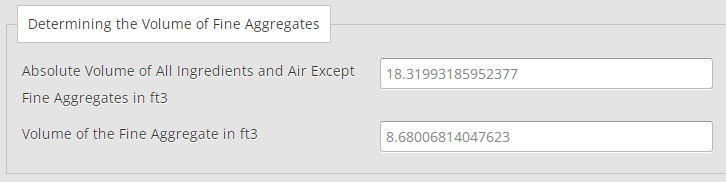

The volume of fine aggregates

This section shows the absolute volume of all the ingredients and air in the mix in cubic feet, except the volume of fine aggregates. The second field shows the volume of fine aggregates, which is equal to the unit volume (27 cubic feet which equals 1 cubic yard) minus the absolute volume of all ingredients and air except the fine aggregates. In this example, the volume of fine aggregates is 8.68 cubic feet.

The water contributed by the aggregates

This section of the concrete mix design calculator informs the user about the water contribution by the aggregates. These values rely on the water absorption and moisture content of the aggregates. In this example, fine aggregates contributed to 50.81 pounds of water per cubic yard of concrete. Whereas, coarse aggregates contributed to negative 30.73 pounds of water per cubic yard of concrete (negative value since the absorption is more than the moisture content).

Conclusion

This concrete mix design calculator is a useful tool which helps in determining the proportions of concrete mixtures based on the ACI code. It also provides various valuable information, notes, checks, and data in order to meet different requirements and understand the calculations.

How can i design a 45 MPa trial mix?

This concrete calculator is capable of designing mixtures with a specified compressive strength between 15 and 45 MPa. However, 45 MPa is also the higher limit for the target compressive strength based on the followed codes. Besides, the target compressive strength is always higher than the specified one, unless the standard deviation is set to zero.

How can i design a 6000 PSI concrete mix design with this calculator?

This concrete mix design calculator has limits for the targeted compressive strength of 6000 PSI for non-air-entrained concrete and 5000 PSI for air-entrained concrete. This does not mean that you can use these limits in the first field which is the specified compressive strength, unless the standard deviation is set to zero.

This concrete calculator performs mix designing for trial mixtures based on ACI 318-19, ACI 211.1-91, and ACI 301-16.